Auto repair is an essential aspect of vehicle ownership, encompassing a wide range of challenges and solutions. Whether you’re a motorcycle owner, auto enthusiast, distributor, or running a garage, understanding the intricacies of car auto repair is vital to ensure safety, performance, and longevity of your vehicle. This guide delves into specific repair issues that may arise, highlights impactful industry developments that shape the repair landscape, provides a thorough cost analysis for repairs, and shares preventive maintenance strategies that can save you time and money. Each chapter is crafted to offer useful insights and actionable tips, empowering you to navigate your auto repair needs effectively.

Specific Repair Issues in Car Auto Repair: Reading Signals Behind Misfires, Leaks, and Brakes

Every car whispers clues before it shouts. A rough idle, a faint squeal, or a scent of burnt oil are messages from complex systems that work together to keep a vehicle moving. In car repair, reading these signals requires patience, curiosity, and a willingness to trace symptoms back to their sources. This chapter ties together common issues drivers encounter, showing how misfires, overheating, leaks, transmission faults, braking problems, electrical faults, suspension symptoms, and cooling concerns begin, reveal themselves, and respond to proper maintenance. When misfires occur, the engine may stumble as cylinders fail to ignite properly, reducing power and increasing fuel usage. If left unchecked, misfires can damage downstream components and the catalytic converter. The root cause often lies in ignition, fuel delivery, or injector issues, and timely diagnosis is essential. Regular checks of spark plugs, coils, and fuel pressure can prevent bigger problems. For more detail on engine cylinder misfires, see a focused resource on causes and diagnostics.

Overheating demands attention because a cooling system that falters lets temperature climb and stresses the engine. Possible culprits include sensor faults, a clogged radiator, a failed electric cooling fan, or restricted coolant flow. Checking temperature readings, coolant level, hoses, and clamps is crucial, and detecting a small leak early prevents gasket damage and downstream trouble. Oil leaks tell a similar story of aging gaskets, worn seals, or misaligned parts that allow oil to escape and burn on hot surfaces. Visible oil spots under the car, a drop in oil pressure, and warning lights deserve immediate inspection to locate the source.

Transmission issues complicate things further. Gear slipping suggests the transmission is not maintaining consistent engagement, possibly from worn clutches or fluid contamination. Delayed engagement, a lag between shifting and motion, often points to low or degraded transmission fluid. Transmission fluid leaks, seen as red or amber stains, alert to a breach in the system that should be addressed promptly. Diagnosis often starts with fluid level and color checks, followed by professional service to address internal wear or seal failures. Costs and complexity vary, so early detection and reliable diagnostics matter.

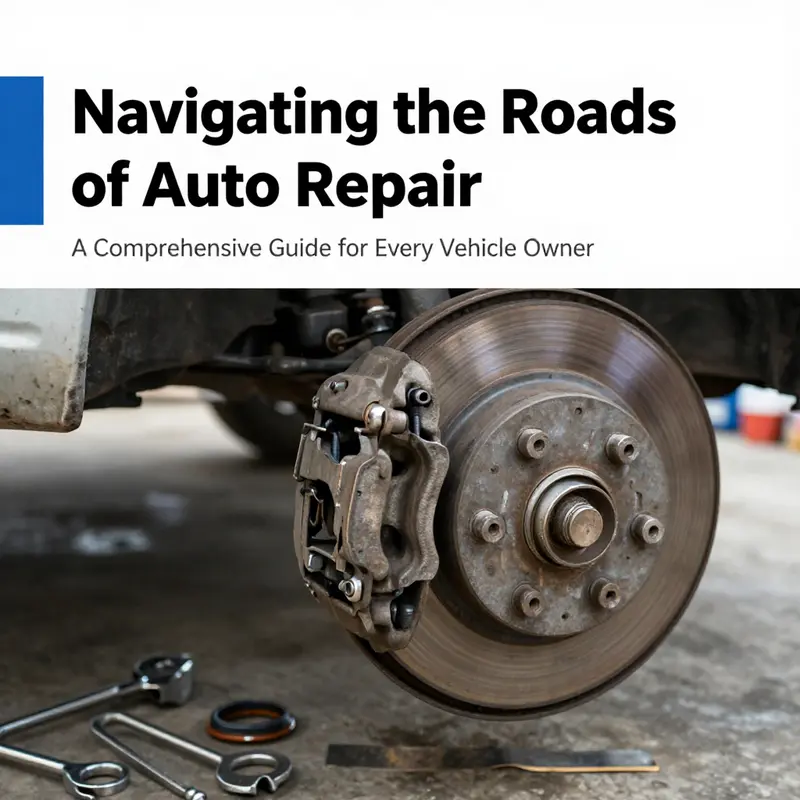

Braking safety is critical. Worn pads are common and reduce stopping power, while squealing brakes usually signal thin friction material. Leaks in the brake fluid system undermine hydraulic performance and can produce a spongy pedal or delayed response. Regular inspection of calipers, pads, discs, the master cylinder, and moisture in the fluid supports safer operation. A planned service interval with pad thickness and fluid checks helps prevent emergencies.

Electrical faults can affect nearly every system. A drained battery, especially in cold weather, or malfunctioning lights point to charging or wiring issues. An alternator failure can cause discharge during operation, and blown fuses or corroded connectors can create cascading symptoms across sensors and modules. Diagnosing electrical problems benefits from a methodical approach: test the battery and charging system, trace circuit continuity, and inspect wiring harnesses for wear or damage.

Suspension and steering issues may be subtler but still critical. Uneven tire wear often signals misalignment or worn bushings, while noisy shocks or struts indicate wear that affects ride comfort and handling. Difficulty steering can arise from power steering fluid leaks, worn rack components, or pump issues. Regular checks of suspension and steering parts, alignment, and tire condition help preserve precise handling and safety.

The cooling system, though less dramatic, is essential for stable operation. Coolant leaks, radiator problems, or a faulty thermostat can disrupt heat management. Regular maintenance like checking hoses for cracks, ensuring proper coolant concentration, and confirming water pump function helps protect the engine from thermal stress that accelerates wear.

The key thread across these issues is preventive maintenance and a disciplined diagnostic approach. Observe the behavior, measure relevant parameters, inspect components for wear, and verify that related systems are not contributing indirectly. Early detection and careful testing reduce time, cost, and risk. When in doubt, seek a professional diagnostic that uses clear scope, transparent reasoning, and reliable parts. This approach helps drivers cooperate effectively with mechanics and keep vehicles safe and dependable.

Industry News Redefining the Garage: Transparency, EV Evolution, and the New Rules Shaping Car Auto Repair

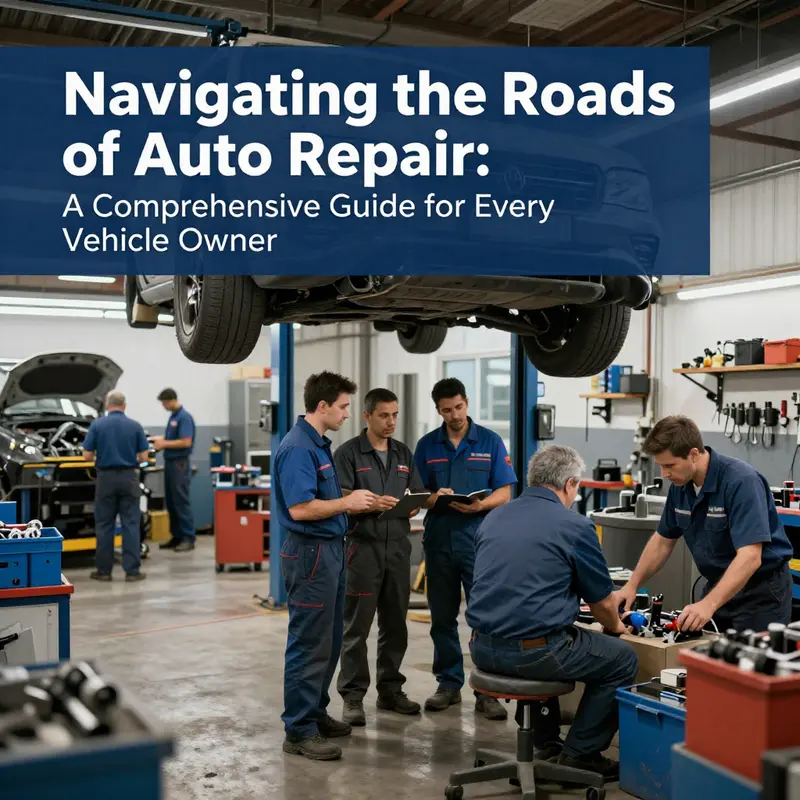

The landscape of car auto repair is transforming into a data-driven, transparency-focused ecosystem. Shifting consumer expectations, rapid tech progress, and new regulatory standards require repair shops to balance traditional diagnostics with digital visibility and safety-compliant processes. As vehicles become more complex, the repair trade must bridge mechanical skill and software literacy, delivering measurable value and accountability.

On the consumer side, studies show a growing demand for transparent pricing, itemized estimates, and proactive communication. Online booking, real-time status updates, and clear explanations about work scope and long-term reliability are becoming baseline expectations. Shops that provide transparent pricing and accessible diagnostic data build trust and encourage repeat business.

Technology fuels this change. The rise of electric vehicles shifts emphasis to battery health, high-voltage safety, and software updates. Technicians need new tools and targeted training to handle battery systems, ADAS calibration, and over-the-air software revisions. Equipment now includes software-defined workstations, battery test rigs, and calibration kits for connected platforms. Regulatory bodies push for safer, more traceable maintenance histories, reinforcing the need for standardized documentation and process controls.

Market dynamics reflect these shifts. Independent shops are expanding services beyond traditional mechanical repairs, including parts sales and battery services, while tooling innovations improve safety and efficiency. Pricing comparisons highlight differences between dealership quotes and independent options, underscoring the tradeoffs between parts quality, warranty considerations, and long-term reliability.

Ultimately, the industry is moving toward a one-stop, data-enabled auto care model. Shops that emphasize end-to-end service, transparent communication, and robust technician training will likely outperform peers relying on a purely mechanical approach. The news from industry campaigns, new entrants, and tooling innovations serves as signals about the road ahead for 2026 and beyond.

The Repair Bill Decoded: Navigating Parts, Labor, and Overhead in Car Auto Repair

Every garage bill is more than the sum of its parts. In car auto repair, the final figure represents a careful balancing act among three core ingredients: parts, labor, and overhead. For consumers, understanding this equation helps separate the truly necessary fixes from wish-list items and sheds light on why two shops can quote very different totals for seemingly identical work. For repair shops, it clarifies where value is created and where costs can drift, inviting more transparent pricing and smarter decisions that keep customers safe and vehicles dependable over the long haul.

Parts costs, in particular, loom largest in most repair bills. Replacement components vary widely in price depending on make, model, year, and the particular system involved. A modern vehicle’s complexity—sensors, control modules, and electronic subsystems—drives part prices higher than ever before. Industry data show that a single part can range from a modest fifty dollars to well over a thousand dollars. When the same repair involves multiple parts, the total can balloon quickly, especially if OEM parts are chosen for reasons of reliability or warranty coverage—though many shops can offer aftermarket or remanufactured alternatives that substantially cut the tab. A striking metric in the market is the so-called zero-to-one ratio, which compares the total OEM-part cost to the vehicle’s original sale price. In some cases this ratio spikes above 300%, illustrating why owners of certain high-value or luxury vehicles face decisions that aren’t purely about fixing one component but about whether the overall repair remains economically sensible.

A concrete way to grasp the economics is through typical cost ranges in a common scenario. For a mid-range sedan valued around 100,000 RMB, a light repair using original parts at an official dealership service center might run roughly 3,000 to 5,000 RMB. A reputable independent shop using branded parts could price the same job lower, around 2,000 to 3,500 RMB. When repairs escalate to more extensive work, such as replacing a critical cylinder head gasket, the dealership route can climb to 8,000 to 12,000 RMB, while independent shops might manage the same task for roughly 5,000 to 8,000 RMB. The gap grows with vehicle value and complexity. For luxury or premium models, the discrepancy between dealership quotes and independent shop estimates can be substantial, underscoring how the decision to repair versus replace becomes a nuanced cost-benefit calculation rather than a single bottom-line number.

Labor costs form the second major component of the bill and reflect the time, skill, and specialization required. Technicians’ hourly rates vary widely by region, shop type, and the expertise demanded by the job. In many markets, average labor rates hover in a broad range that can start around the low double digits per hour and rise toward the higher end in urban or specialized facilities. As vehicles have grown more technologically complex, diagnostic time has increased as well. The modern repair often begins with sophisticated computer-assisted diagnostics to identify root causes embedded in software and sensors, not just mechanical wear. This shift has pushed the average time required for diagnostics higher than previous decades. In many cases, a diagnostic check now consumes notably more hours than in the past, and the need for certified technicians—especially for advanced systems such as high-voltage battery safety in electric vehicles—adds to the labor cost, even before any parts are ordered.

Beyond the shop bench, overhead costs also color the repair bill. A shop must cover rent or mortgage for its space, utilities, insurance, ongoing training, diagnostic software subscriptions, tooling, and inventory management. These fixed costs are spread across every job, so even a single-hour variance in labor or a minor delay in parts delivery can nudify the final estimate. To manage these pressures, many shops pursue efficiency gains through preventive maintenance programs, which reduce emergency repairs and keep customers on a steadier, lower-cost maintenance cadence. Others look to aftermarket or remanufactured parts as a way to trim costs while maintaining reliability, though this choice can depend on the vehicle, warranty requirements, and customer preference. Digital workflow systems, for instance, have demonstrated tangible benefits. A widely cited industry study found that shops using digital work-order platforms experienced fewer administrative errors and faster turnaround times, with improvements in customer communication translating into higher satisfaction. The practical upshot is that overhead can be managed more effectively when shops invest in the right mix of technology, process discipline, and supplier relationships.

Looking at trends helps connect the math to the future. The growing integration of ADAS features, connectivity, and over-the-air updates means repairs often require not only mechanical know-how but also software diagnostics and programming. Part prices may continue to be influenced by semiconductor supply and material costs, making the parts portion of the bill more volatile than in the past. The industry is increasingly turning toward remanufactured parts and recycling programs to curb expenses and environmental impact, while still meeting safety and performance standards. On the pricing side, regulators and insurers in some regions are beginning to factor repair complexity and part scarcity into risk-based pricing models, nudging manufacturers toward designs that balance performance with maintainability.

For consumers, these dynamics translate into practical strategies. First, when a repair decision involves multiple components, ask for an itemized breakdown that clearly shows parts, labor, and overhead. Itemized estimates reduce surprises and help you compare apples to apples across shops. Second, consider the total cost of ownership, not just the immediate bill. A repair that preserves the vehicle’s value and reliability may be preferable to a cheaper fix that yields repeated visits and incremental expense over time. Third, inquire about alternatives to OEM parts when appropriate. Aftermarket or remanufactured components can offer substantial savings without compromising safety, especially for non-critical systems, while still carrying manufacturer-approved warranties when offered by reputable suppliers. A transparent shop will explain the pros and cons of each option, including any potential impact on warranties, resale value, or future service needs.

To connect these ideas to everyday practice, many owners benefit from a practical awareness of pricing norms and communication practices in the repair industry. For readers seeking a grounded, consumer-friendly view of how pricing is presented and justified, a comprehensive guide that emphasizes clear explanations and honest estimates can be a helpful companion in the decision-making process. A-to-Z Auto Repair, for instance, offers broad guidance on auto repair workflows and pricing expectations, which can empower customers to engage more confidently with service providers. See more at the referenced guide: A-to-Z Auto Repair.

The decision frame changes further when maintenance culture shifts from reactive fixes to proactive care. Preventive maintenance, driven by regular inspections and scheduled replacements of wear-prone components, can dramatically reduce the likelihood of high-cost emergencies. In the end, the cost analysis in car auto repair is less about chasing the lowest price and more about achieving a reliable, safe vehicle at a fair, predictable cost. The aim is to minimize the number and severity of surprises while maintaining the vehicle’s performance and safety margins. This requires a combination of transparent estimates, informed choices about parts and services, and a shared understanding between the customer and the shop about long-term value.

External context helps round out the picture. For readers who want a broader perspective on industry cost dynamics, the 2025 State of Automotive Repair Report provides a comprehensive benchmark of labor rates, parts pricing trends, consumer behavior, and how technology is shaping the repair landscape across regions. Access to the broader data can help readers gauge local quotes against national trends and understand how national shifts in parts availability, tooling, and training influence the bills they receive. External resource: https://www.aaanews.org/2025-state-of-automotive-repair-report/.

Guardrails on the Road: Building Reliability Through Preventative Maintenance in Car Auto Repair

Preventative maintenance is the quiet engine behind reliable, safer driving. It is the deliberate practice of tending to a vehicle’s health before a breakdown forces a costly repair or leaves a driver stranded. In a field where complexity grows every year, this approach shifts the paradigm from reaction to foresight. Modern cars are marvels of engineering, yet they conceal hidden weaknesses that unfold only with time, mileage, or environmental stress. The result is not catastrophic failure in every case, but the kind of gradual wear that erodes efficiency, safety, and resale value. The argument for preventative maintenance rests on real-world data and practical experience: a notable portion of new vehicles harbor latent mechanical faults within the first three years, faults that become visible only through careful inspection and routine service. Treating these issues early avoids cascading problems that would otherwise escalate into expensive repairs or unsafe situations. The truth is simple and powerful: if you don’t check, you won’t know. Consider the scenario of a premium European sedan, well cared for in terms of general upkeep, yet developing micro-cracks in a drive belt that lead to heat buildup, noise, and, in worst cases, a sudden loss of power. Such incidents aren’t inevitable, but they are plausible unless a maintenance plan catches them before they become emergencies. This is why preventative maintenance should be seen not as a discretionary expense but as an essential component of responsible car ownership, a form of proactive risk management that pays for itself over time through reduced breakdowns, safer operation, and preserved value.

To move from philosophy to practice, most successful maintenance programs rest on a simple, repeatable approach: regular inspections, targeted service actions, and meticulous record-keeping that translates into a clear, actionable path for ongoing care. A practical way to frame this is the concept of a point-check routine—sporadic, one-off servicing gives way to a structured discipline that aligns with the vehicle’s design and the owner’s usage. At its core, this approach focuses on four interrelated areas that collectively safeguard the car’s vital systems and performance. First is the drive train and transmission, where a routine check looks for cracks, looseness, and unusual noises that could signal misalignment or wear. Second are belts and chains, the lifelines that synchronize the engine’s operations; surface cracks, fraying, glazing, and correct tension require timely attention, because a failed belt can seize an engine or trigger costly damage. Third is the cooling system, an often-overlooked domain where tiny leaks, degraded hoses, or a worn water pump can precipitate overheating and expensive repair bills if ignored. Fourth is the electrical system, the nervous system of a modern vehicle; corrosion on battery terminals, loose terminals, or deteriorating wiring can produce unpredictable power loss and electronic faults in a car that relies heavily on sensors and control modules. These four areas form the backbone of a coherent preventative plan, and the specifics matter: inspection intervals for the drivetrain and transmission tend to be scheduled around 20,000 kilometers or as part of major services; belts and chains benefit from checks every 15,000 kilometers, with replacement intervals commonly spanning 60,000 to 100,000 kilometers, depending on design and operating conditions; the cooling system calls for biannual checks with a full flush and refill every couple of years; and the electrical system should be examined at each oil change or seasonal check, given how much vehicles rely on consistent electrical supply for performance and safety features. Along the way, owners should pay attention to the brake fluid, which a standard preventive practice keeps refreshed every two years or roughly 40,000 kilometers. This cadence, while not universal, reflects a consensus in the trade that small, routine actions prevent large, unpredictable failures.

Incorporating these checks into daily life requires organization and a mindset shift. A digital maintenance tracker—whether an app or a simple spreadsheet—transforms intention into action by logging dates, mileage, and observations. It serves as a memory aid for both owner and technician, ensuring no inspection is skipped and every service is aligned with the vehicle’s needs. The benefit is not merely fewer surprises; it is a clearer window into the car’s health that builds confidence among drivers and passengers alike. The measured pace of preventative maintenance is a hedge against the sudden, often dramatic costs of repair. It is also a meaningful contributor to safety. Brakes, tires, lights, and steering are the first lines of defense on the road, and the meticulous care of their supporting systems translates into safer handling, longer tire life, and better stopping power when it matters most. The financial reward is not abstract either. Replacing a worn belt today costs a fraction of the price of a seized engine caused by neglected timing components or coolant failures that allow overheating to bake vital seals and gaskets. A maintenance history, documented and verifiable, can also enhance resale value by giving prospective buyers a transparent narrative of care rather than a tale of unknowns.

Beyond the routine tasks, preventative maintenance evolves with the broader industry shifts toward smarter, connected vehicles. A growing body of evidence emphasizes that proactive monitoring, diagnostic data, and even AI-powered forecasting can anticipate wear and optimize service timing. Yet even without advanced predictive tools, the fundamentals remain effective and accessible. The premise is straightforward: regular checks enable early detection of hidden faults, reducing the risk of roadside breakdowns and unexpected downtime. As a practical rule of thumb, owners can map a four-point baseline inspection—the same one mechanics use to structure visits—into a personal schedule that fits driving habits and local conditions. The essence lies in consistency and the willingness to adjust as the vehicle ages and as technologies evolve. When an owner commits to a reliable maintenance rhythm, the car becomes a partner rather than a gamble on the road.

The choice between different maintenance philosophies is not only about intervals but about how to leverage data. A time-based approach emphasizes fixed intervals, such as oil changes and tire rotations, while a usage-based plan ties service to mileage, and condition-based strategies rely on real-time health signals captured by sensors. For owners aiming to embrace the future, predictive maintenance—driven by AI and connected car platforms—offers a prospect of even more precise service windows. In truth, most drivers will find a hybrid model that combines time- and usage-based checks with occasional condition-based diagnostics to be practical and cost-effective. The U.S. Department of Energy’s Vehicle Maintenance Best Practices outlines a science-backed framework for these schedules, highlighting how early fault detection pays off through lower repair costs and fewer sudden failures. While the language of policy and industry reports can feel distant, the message is concrete: prevention should be the default, not the exception.

The concrete benefits of this approach extend beyond the obvious. Routine preventative maintenance reduces the likelihood of breakdowns by a meaningful margin, often cited as up to half the incidents drivers experience on the road. It also extends the vehicle’s life by preventing the cumulative wear that chips away at performance and efficiency. Financially, the math is favorable: replacing a small belt or worn hose is far cheaper than repairing a seized engine or addressing a damaged component that compromised nearby systems. And safety, the ultimate objective, improves as mechanics catch issues that could affect braking, steering, or heating and cooling during critical moments. A maintenance history, well-kept and transparent, also reassures buyers and can smooth resale negotiations, since the vehicle’s care pattern becomes part of its value proposition.

A final takeaway reinforces the necessity of action. Good maintenance is not about treating a car as a perpetual motion machine but about treating it as a well-worn companion that deserves ongoing attention. It requires discipline, a willingness to adapt to changing needs, and a basic level of literacy about the vehicle’s systems. In the march toward smarter, more connected cars, preventative maintenance remains a reliable anchor—part tradition, part technology, and wholly practical. For readers who want to explore the broader landscape of repair knowledge, the internal resource A to Z Auto Repair offers a textured overview of comprehensive care and maintenance routines that align with the four-point framework described above. A to Z Auto Repair provides context and continuity for readers who wish to translate this chapter’s guidance into a broader personal maintenance habit.

In addition to these internal anchors, external resources reinforce the rationale for preventative care. The U.S. Department of Energy’s Vehicle Maintenance Best Practices presents a formal, evidence-based primer on schedules, fault detection, and the cost consequences of neglect. It is a useful companion to the more practical, hands-on guidance offered here, tying everyday checks to larger efficiency and safety outcomes. The combination of practical discipline and science-backed principles creates a robust framework for any driver seeking to reduce risk and costs while preserving the integrity of their vehicle over the long haul.

External reference: U.S. Department of Energy – Vehicle Maintenance Best Practices.

Final thoughts

Understanding the nuances of car auto repair is crucial for anyone involved in vehicle ownership or the automotive repair industry. By addressing specific repair issues, staying informed about industry developments, analyzing repair costs, and adopting preventative maintenance practices, vehicle owners and repair shops alike can promote safety and efficiency. Embracing this knowledge empowers you to make informed decisions about your vehicle, fostering a more reliable and enjoyable driving experience.