In the ever-evolving auto repair industry, A and R Auto Repair stands out as a beacon of quality and integrity. With a focus on both motorcycle and auto owners, our commitment to excellence encompasses not only top-notch repairs but also a profound understanding of the workforce dynamics and the challenges faced by technicians. Each chapter delves into critical aspects of our operation, beginning with the employment dynamics at A and R Auto Repair, where we highlight the importance of skilled labor in shaping our services. Following this, we will explore the informal economy prevalent in auto repairs, shedding light on the unique challenges that come with it. Talent and skills development are vital components of our strategy to foster a knowledgeable workforce, which will be discussed in detail. We will then turn our gaze towards technological innovations that are transforming the industry, enhancing service delivery and efficiency. Finally, best practices in workshop management will equip readers with insight into maintaining a well-oiled operation that benefits auto repair shops and garages. Together, these chapters will provide a comprehensive understanding of how A and R Auto Repair prioritizes excellence in every facet of our business.

Chapter 1: Steering Employment Dynamics in A&R Auto Repair: From Informality to Innovation in a Shifting Labor Landscape

The auto repair industry sits at a crossroads where the wheels of everyday mobility meet the edges of formal work and evolving technology. Across many regions, the labor force in vehicle repairs and services illustrates a paradox: a sizable, essential workforce operating in a subsistence-leaning informal economy even as the sector stabilizes with modern business models and new skill demands. National and regional snapshots, such as the ILO Brief Overview of Workers in the Subsector of Vehicle Repairs & Services from July 2023, quantify the scale of the sector—approximately 96,347 workers, about 1.3 percent of the regional workforce. Yet the same studies reveal a heavy tilt toward informality: 88 percent of auto-repair workers are informal, and 92 percent operate under informal arrangements. These figures are not mere statistics; they map the daily realities of thousands who fix, tune, and restore vehicles with limited access to social security nets, formal licensing, and consistent job security. Within this context, the employment structure is notably bifurcated. Employees account for about half of total employment, while self-employment dominates the other half, with employers and own-account workers together representing roughly 45 percent of the workforce. The clustering of informal employers—around two-thirds of employers—highlights a landscape where small shops often operate outside formal registration, even as a substantial share of informal workers do secure some stability by working from fixed locations. These patterns matter because they shape eligibility for training, career progression, and protections that can improve job quality and industry resilience in the face of rapid change.

Against this backdrop, A&R Auto Repair in Clarksville, Tennessee, appears as a microcosm of both the challenges and opportunities described in the broader picture. The company is actively expanding its workforce to align with the shifting demands of a modern auto sector that increasingly blends traditional mechanical skills with high-tech diagnostics and new propulsion technologies. Current job postings indicate a deliberate effort to attract skilled technicians by offering competitive pay and a scheduling model designed to support work-life balance—no weekend shifts. This flexibility addresses a well-known pain point in the repair trade: the toll of long, irregular hours on technician retention and morale. In an industry where burnout and turnover can undermine service quality, such scheduling flexibility is not a mere perk; it is a strategic pillar for sustaining a capable workforce that can meet rising customer expectations.

What makes A&R Auto Repair particularly instructive is its proactive stance on the technological frontier. The company has signaled a commitment to the Net Zero initiative and is investing in training and infrastructure to service electric vehicles. This is more than a nod to environmental concerns; it is a practical repositioning of the workforce for a future where electric powertrains, high-voltage systems, and advanced diagnostics become standard fare rather than niche specialties. Preparing the shop floor and the people on it for EV service opens multiple avenues for employment growth. Technicians will gain high-value, saleable skills in areas such as battery health assessment, thermal management, and safety procedures around high-voltage systems. The result is not only a more versatile service offering for customers but a path to longer, more secure career trajectories for technicians who invest in continuing education and hands-on experience with cutting-edge technology. In this sense, A&R Auto Repair embodies a bridge between the traditional craft of auto repair and the modern competencies required in a decarbonizing, electrified vehicle ecosystem.

Within the labor market at large, the ILO’s findings illuminate both the fragility and the potential of formalization in the auto repair subsector. Formal employment—complete with social security coverage, licensing, and predictable career ladders—offers tangible protections and benefits that can uplift workers and lift the sector’s standards. Yet formalization is not simply a bureaucratic reform; it requires a transformation of business models, financing, and market incentives. Small, informal shops often lack the resources to bear compliance costs or to invest in specialized training without a clearer return on investment. They also operate in dense, competitive local markets where customer trust is earned through speed, reliability, and price—factors that can be at odds with the costs and processes of formal compliance. A&R Auto Repair’s approach suggests a practical pathway: combine formal protections and growth-oriented training with flexible scheduling and a modern service portfolio to attract skilled technicians who might otherwise drift toward other industries or gig work. By doing so, the shop not only stabilizes its own workforce but also contributes to a broader narrative in which formal, well-trained technicians become the standard rather than the exception in a reforming sector.

The chapter’s focus on employment dynamics hence moves beyond a single firm to address structural questions: How can a growing shop recruit and retain qualified workers in a landscape where informality remains prevalent? How does a shift toward EV service reshape demand for different skill sets, and what career pathways does that create for technicians at various stages of their professional lives? The Clarksville example shows that demand-side signals—service diversification, commitment to sustainability, and a workplace culture that values balance and professional development—can attract talent even in markets with a substantial informal presence. The talent pipeline is as important as the shop’s equipment and layout. For technicians, the promise of stable hours, competitive pay, ongoing training, and a clear line of sight to advancement can transform the economics of work in a sector where many workers are self-employed or operate small, informal businesses. For employers, this means higher productivity, better service quality, and greater capacity to scale. The alignment of incentives—protecting workers’ welfare, investing in capabilities, and delivering reliable, modern services—creates a virtuous circle that strengthens the shop’s reputation and customer trust.

This dynamic also intersects with broader modernization efforts in the auto repair ecosystem. Platforms and collaborative models—often described as shared-service platforms—emerge as practical mechanisms to address talent shortages, improve job matching, and optimize knowledge sharing across the network of shops and technicians. While some discussions frame these innovations as disruptive forces, a more constructive view sees them as accelerators of professional development and workforce stability. They can help standardize training paths, reduce recruitment costs for shops, and expand opportunities for technicians to access work from multiple employers without sacrificing the security and benefits associated with formal employment arrangements. In practice, a well-orchestrated platform can connect a shop facing a backlog with a pool of qualified technicians, streamline dispatching, and enable on-demand service booking that keeps the customer experience consistent. For a shop like A&R Auto Repair, the strategic use of these platforms can complement internal hiring practices, expand capacity to handle EV service lines, and provide a more predictable workflow that supports longer-tenure retention.

In tying these threads together, this chapter considers the intersection of formal employment practice, skill modernization, and innovative business models. The data from the ILO signals a sector in transition, where formal jobs offer social protections and career opportunities but must be made accessible and financially viable for small businesses and independent workers alike. A&R Auto Repair’s experiential path—stable scheduling, EV readiness, and a mature investment in people—illustrates how a shop can chart a course that respects the realities of a mixed labor market while advancing toward a more resilient and capable service ecosystem. The narrative of this chapter is thus not a triumphalist tale of formalization alone but a nuanced exploration of how formal and informal elements can co-evolve. By anchoring workforce strategy in training, safety, and sustainable practice, and by embracing flexible scheduling and scalable service lines, auto repair shops can attract and keep skilled technicians who will carry the industry forward in a rapidly changing era.

To ground this discussion in practical resources, readers may explore a concise primer on auto repair basics that foregrounds the foundational trades and knowledge common to most shops, including the kinds of capabilities likely to be required as service portfolios expand. See the resource linked here: A to Z Auto Repair. This reference point helps connect the theoretical discussion of employment dynamics to concrete, everyday practice in a modern shop. The path from ILO-wide observations to Clarksville’s shop floor is not linear, but it is instructive: invest in people, plan for evolving technologies, and create work arrangements that support both stability and skill growth.

External resource: For a broader policy perspective on employment security and informal work within the automotive subsector, see the International Labour Organization’s overview of employment security and informal arrangements in vehicle repairs and services. https://www.ilo.org/global/topics/employment-security/lang–en/index.htm

null

null

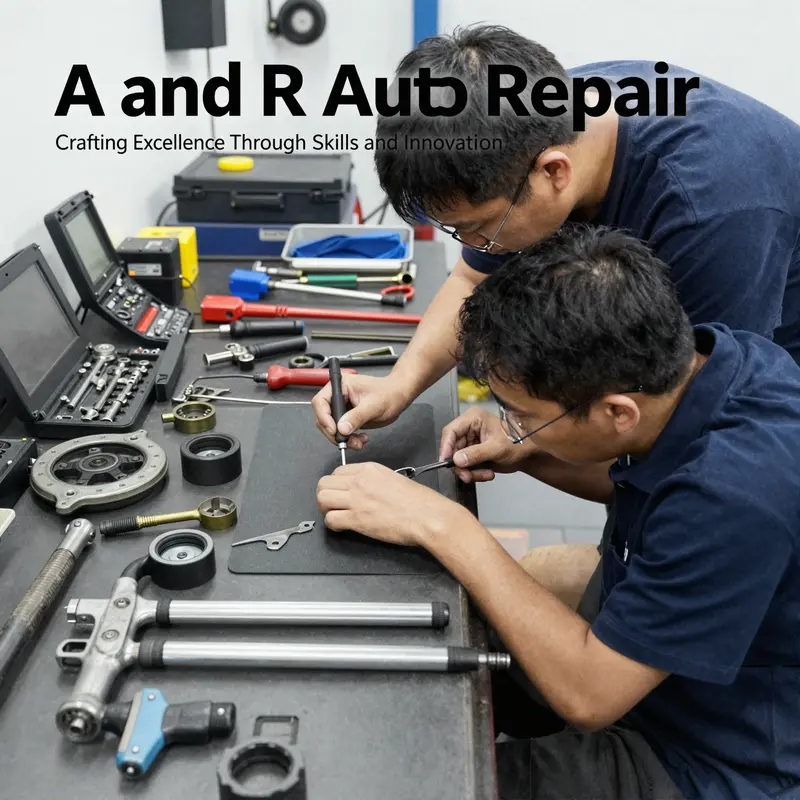

Chapter 3: Building a Future-Ready Workforce for EV-Driven Auto Repair

The auto repair industry stands at a pivotal moment. It is no longer enough to be proficient with spark plugs, timing belts, and carburetors; the next generation of technicians must navigate high-voltage safety, battery management, rapid electrical diagnostics, and software-driven systems. This shift is not a distant prospect but a present demand that companies like A&R Auto Repair and Services, LLC are embracing as part of a broader strategy to align talent with a Net Zero mission and the ongoing adoption of electric vehicles (EVs). The broader labor landscape mirrors both opportunity and challenge. A recent global snapshot underscores that the auto-repair subsector comprises roughly 96,347 workers, about 1.3 percent of the regional workforce in the studied area. Yet the sector remains largely informal: roughly eight in ten workers operate outside formal arrangements, and nearly nine out of ten are in informal employment. This reality is not just a statistic; it shapes the way skills are developed, how risks are managed, and how service quality is guaranteed across shops of varying scales. Within this milieu, the employment mix is telling: about half of all workers are employees, while almost half are self-employed in some form, including employers and own‑account practitioners. A sizable portion of employers—especially in the informal segment—are concentrated in smaller, fragmented operations. And despite a need for operating licenses, compliance remains uneven, which can complicate workforce planning and formal training initiatives. All of this matters because talent is the first-line defense against EV reliability problems and the customer experience gap that often accompanies rapid tech adoption. It also signals where reform advocates and industry leaders must focus: on formalization that preserves flexibility while expanding social protections, and on scalable, practical training that transfers from the classroom to the shop floor with measurable results. The industry’s evolving talent landscape is not just a regulatory or economic issue; it is a question of how to sustain and elevate service quality as vehicles become more technologically complex, connected, and energy-conscious. The emergence of shared-service platforms, such as Auto Repair House, signals one potential pathway. These platforms connect repair shops with skilled technicians, enabling online task postings and on-demand bookings. They promise to reduce recruitment costs, accelerate talent matching, and facilitate knowledge sharing—an important advantage in markets where talent shortages can bottleneck service capacity. In practical terms, such platforms can help a shop scale up its EV service offerings without being constrained by traditional hiring cycles. For technicians, these networks can broaden opportunities for work, allow them to build diverse hands-on experience, and create pathways for ongoing skill enhancement through exposure to a wider range of vehicles and diagnostic scenarios. The net effect is a more flexible, responsive ecosystem in which both employers and technicians can grow. Yet platform-enabled agility does not replace the imperative for structured, forward-looking training. At A&R Auto Repair, the strategy is to build a robust talent pipeline that spans initial entry skills, advanced diagnostics, and specialized competencies required for NEV repair. The company recognizes that simply repurposing existing ICE repair skills into EV work is insufficient. High-voltage safety protocols, battery health assessment, thermal management, regenerative braking systems, and software-driven fault diagnosis demand a level of rigor and safety discipline that cannot be improvised. Consequently, A&R is prioritizing comprehensive upskilling for current technicians while simultaneously recruiting new talent with a predisposition for electrified powertrains. This means expanding training beyond traditional mechanical repair into a broader, more interdisciplinary skill set that includes electrical engineering concepts, data interpretation, and cyber-physical systems awareness. In effect, the organization is training for a future where a technician is as comfortable with a multimeter as with a diagnostic cloud, where fault codes are as familiar as torque specs, and where safety is embedded in every procedure as a first principle. The company’s talent and skills development plan is forward-looking while pragmatically grounded in the realities of today’s labor market. It aligns with a growing industry norm: invest in continuous professional development to sustain service quality, customer trust, and competitive differentiation in an increasingly electrified market. The best-in-class approach to training mirrors the broader industry pattern that emphasizes structured programs and continuous learning. While the exact program names may not be enumerated in the available materials, A&R’s philosophy draws on established models that prioritize practical innovation, leadership development, and problem-solving capabilities. In this sense, the company is not merely teaching technicians to fix cars; it is cultivating “extraordinary talent” capable of adapting to fast-moving technologies, shifting customer expectations, and evolving business models. This is where the concept of a sustainable talent pipeline becomes central. The shortage of new energy vehicle (NEV) repair technicians is well documented, with a lack of standardized national vocational qualifications and a limited educational pipeline exacerbating the gap. A&R addresses this challenge head-on by forging internal training programs that map clearly from entry-level competencies to advanced EV-specific skills. In addition, the company actively seeks partnerships with educational institutions to create a steady stream of qualified entrants who can transition smoothly into shop floors that demand higher levels of technical literacy and safety proficiency. Such collaborations are two-way streets: schools gain real-world relevance through structured apprenticeship and internship opportunities, while A&R gains access to a more diverse pool of motivated talent with fresh perspectives and up-to-date academic foundations. This collaborative model helps to bridge the “know-how” gap that many NEV repair sectors face when national curricula do not yet codify EV-specific standards. It also complements the informal labor dynamics highlighted in broader sector analyses. While a significant portion of the workforce operates informally, formal training initiatives anchored in credible partnerships can progressively shift the balance toward higher skill levels, better wage security, and clearer career progression paths. In practical terms, this means that technicians are not only learning to diagnose a fault but also to communicate diagnostic results clearly to customers, to navigate the regulatory and safety dimensions of high-voltage work, and to manage job planning in a way that aligns with the shop’s service portfolio and the customer’s needs. Leadership development and entrepreneurship are also woven into the talent strategy. The cited industry practices show that companies investing in leadership capabilities—through structured development programs and cross-functional exposure—tend to emerge with teams that are not only technically competent but also agile, collaborative, and capable of driving operational improvements. The reference point from broader industry programs—like those associated with recognized training ecosystems—illustrates the value of long-term workforce planning, mentoring, and experiential learning as anchors for sustainable growth. Even without naming specific program titles, the underlying premise is clear: the most resilient auto repair businesses will be those that treat skills development as a strategic asset rather than a peripheral function. Within A&R Auto Repair, this translates into a deliberate, staged progression. Technicians begin with foundational ICE skills, then receive targeted EV certifications that emphasize high-voltage safety protocols, battery health assessment, and battery management systems. They move into advanced diagnostics, where data interpretation and software tool proficiency become core competencies. They cultivate customer-facing communication skills that improve trust and transparency in EV service encounters. And they participate in leadership and entrepreneurial training that encourages problem-solving, process optimization, and service diversification. This holistic approach yields tangible benefits. A skilled, future-ready workforce can deliver higher-quality EV maintenance and repair, speedier diagnostic cycles, and safer, more reliable high-voltage work. It also enables A&R to respond with greater agility to market shifts, such as surges in EV adoption, changes in warranty requirements, and evolving industry standards. Importantly, the company’s strategy recognizes that talent development is inseparable from operational modernization. The sector’s move toward formalization—elevating the professionalism of the workforce and expanding social protections—depends on credible training that demonstrates measurable competencies. A&R’s investments in internal training and in partnerships with education providers are steps toward constructing a more formal, capable, and accountable talent pool. They are also essential for sustaining a consistent service standard that can win customer trust and support Net Zero ambitions by ensuring that EV services are delivered safely, efficiently, and cost-effectively. Looking ahead, the journey is as much about people as it is about machines. A skilled workforce is the backbone of modernization, enabling more shops to offer EV services with confidence, expanding access to high-quality repairs, and building resilience in a sector that has historically faced fragmentation and informality. By integrating talent development with strategic goals—environmental stewardship, customer satisfaction, and business growth—A&R Auto Repair positions itself not merely to adapt but to lead in an era where vehicles are technologically sophisticated and energy-conscious. For readers seeking a practical touchstone on shop processes that support this kind of development, a concise resource can be found at A-to-Z Auto Repair. A-to-Z Auto Repair offers a gateway to comprehensive, end-to-end shop practices that can complement formal training with real-world workflow discipline. The path ahead will require ongoing investment, disciplined accountability, and a culture that values continual learning as much as it values customer safety and reliability. When these elements align, the auto repair workforce can truly become a catalyst for industry modernization, delivering better outcomes for technicians, shops, and the customers who rely on them. This is not merely an upgrade in skills; it is a transformation in mindset, one that honors the present while boldly preparing for the electrified road ahead. For broader industry context on talent development in the field, see the external discussion on talent development initiatives at https://www.sherwin-williams.com/careers/talent-development.

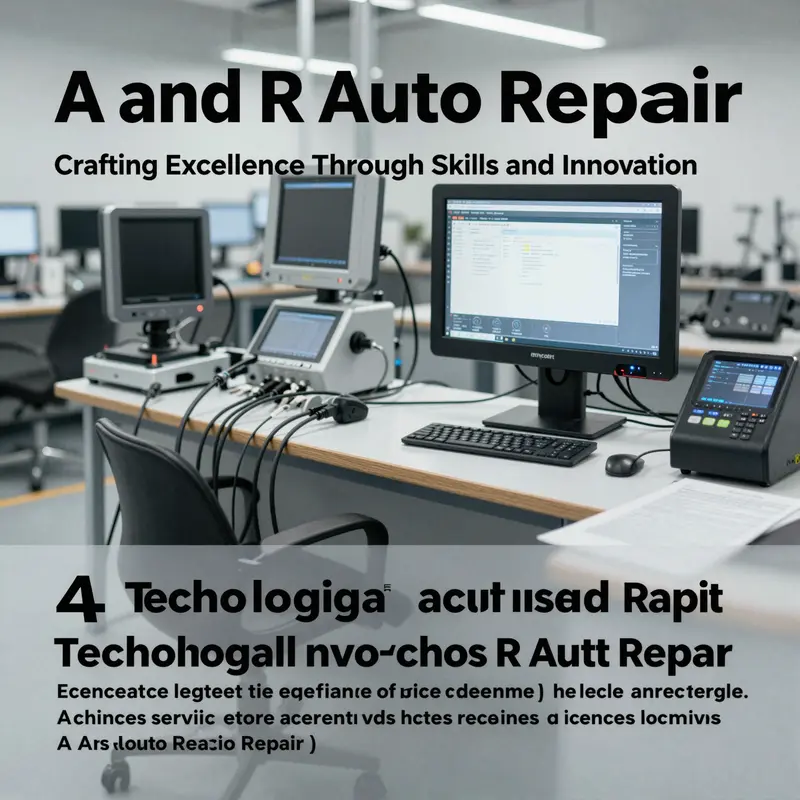

Chapter 4: From Predictive Diagnostics to Connected Cars—How Technology Is Transforming A and R Auto Repair

The repair shop floor is no longer a solitary workshop where a technician relies on intuition and a handful of manual tools. It is increasingly an information-driven environment where data streams, smart devices, and networked systems converge to redefine what it means to diagnose, maintain, and repair vehicles. For A and R Auto Repair, the shift is as much about staying ahead of breakdowns as it is about delivering reliable, timely service to customers who depend on their vehicles for work, family, and safety. The current propulsion of change comes from several interlocking technologies that together reshape every phase of the service cycle—from the moment a fault is detected to the moment a vehicle leaves the bay with a note of confidence and a promise of longer, trouble-free operation. In this context, the most consequential advances are the rise of AI-enhanced diagnostics, the integration of telematics and connected-vehicle data, the adoption of augmented reality and virtual reality for training and guidance, and the sweeping changes driven by electric vehicles and their high-voltage architectures. Taken together, these trends create a more proactive, precise, and transparent repair paradigm that can dramatically improve shop efficiency, customer satisfaction, and long-term business resilience.

Advanced diagnostic capabilities are at the heart of this transformation. Modern vehicles generate an enormous amount of real-time information from thousands of sensors embedded in the engine, transmission, braking system, suspension, and even the infotainment module. Traditional diagnostics—relying on manual checks and basic diagnostic trouble codes—are proving insufficient for the complexity of contemporary powertrains and software-defined subsystems. AI-driven diagnostic platforms that interpret sensor data, patterns of wear, and historical fault histories can spot subtle anomalies that a human technician might miss until a later, more costly failure occurs. Predictive maintenance becomes a practical reality when algorithms analyze patterns in driving behavior, engine load, temperature cycles, and battery health to forecast when components such as alternators, brake pads, or cooling systems will degrade beyond usefulness. This capability reduces downtime for customers and helps a repair shop demonstrate foresight—an important trust signal in a market where reliability is a competitive differentiator. The value of predictive insights goes beyond a single appointment; it shapes a shop’s staffing, parts stocking, and scheduling practices, enabling a more streamlined workflow that minimizes idle time and allows technicians to apply their expertise precisely where it is needed most.

Telematics and connected-vehicle technology extend diagnostic reach far beyond the firm’s four walls. Vehicles increasingly communicate with manufacturers, fleets, and authorized repair centers through built-in cellular or hybrid connectivity. When a shop can access secure streams of vehicle health data—such as battery status, tire pressure trends, misfire patterns, or software anomalies—technicians can prepare for inbound work with a high degree of specificity. Real-time alerts about faults allow for pre-arrival triage, reducing vehicle downtime and increasing the likelihood that the right parts are on hand when the vehicle arrives. In some cases, remote diagnostics can resolve issues without a trip to the shop, a capability that is especially appealing to fleet operators who must minimize downtime and operational disruption. Embracing secure data exchange with manufacturers or approved telematics platforms also carries strategic advantages: it opens avenues for software-driven service campaigns, recalls, and over-the-air updates that can be executed with proper authorization. As vehicles become more software-defined, the importance of robust cybersecurity and data governance becomes a daily operational consideration, not a back-office afterthought.

Training and guidance are increasingly immersive, thanks to augmented reality (AR) and virtual reality (VR). For technicians, AR-enabled devices can overlay digital schematics, wiring diagrams, and step-by-step repair instructions directly onto the physical components being serviced. This layered visualization reduces guesswork, shortens apprenticeship curves, and mitigates the risk of human error on complex systems, such as high-voltage modules in hybrid and electric powertrains. VR simulations provide safe, repeatable environments to practice repairs on rare or dangerous configurations, enhancing skill retention and safety—an essential factor when dealing with high-voltage systems or advanced driver-assistance software that can confound even experienced technicians. In a shop that prioritizes continuous learning, AR and VR become not only training tools but also real-time knowledge conduits, guiding technicians through intricate service procedures with an auditable trail of steps completed and outcomes achieved.

The electrification of vehicles is a defining structural shift that reverberates through every facet of repair practice. Electric vehicles introduce fundamentally different fault profiles, require specialized diagnostics for high-voltage systems, and demand careful battery handling and thermal management. A shop that aspires to be a long-term partner for customers must invest in certified EV technicians, HV safety training, and infrastructure designed to accommodate battery work. This includes tools and protocols for safe disconnection of high-voltage systems, dedicated workstations for battery service, and software access to manufacturer-grade vehicle information and diagnostic platforms. The implications extend to parts inventory, service pricing, and the timing of interventions. Software updates, increasingly delivered over the air, can modify how a vehicle behaves after a repair, demanding ongoing access to manufacturer software platforms and continual training to interpret new fault codes or recalibration requirements. The EV era does not simply add new components to fix; it expands the cognitive map that technicians use to understand how a vehicle operates and how to return it to reliable performance.

Beyond the technologies themselves lies a broader transformation of the repair enterprise model. As the industry moves toward more formalized, technology-enabled practices, the line between a traditional workshop and a data-driven service provider becomes blurred. This evolution creates opportunities to standardize workflows, implement robust quality assurance, and improve customer transparency. Data and process discipline emerge as competitive advantages: precise turnaround times, traceable repair histories, and predictable maintenance schedules become as important as the repairs themselves. In a landscape where informal arrangements once dominated, formalization carries tangible benefits for workers and owners alike. The ILO’s observations on informal employment in the auto-repair subsector suggest both challenges and opportunities. Where formalization is limited, there is a real need for scalable, low-friction solutions that can help small shops access social security coverage, formal employment arrangements, and fair working conditions while preserving the flexibility that makes many local businesses viable. Technology can act as a catalyst here—providing the tools that enable better scheduling, safer work practices, and more transparent interactions with customers, regulators, and talent networks.

This chapter’s thread remains tightly woven with practical realities on the shop floor. Modern diagnostic engines and data analytics do not exist in a vacuum; they must translate into tangible improvements in speed, accuracy, and peace of mind for customers. The integration of telematics, for instance, can support proactive maintenance reminders that keep fleets on the road and reduce unscheduled downtime. For a shop serving a mixed customer base, including private owners and small fleets, the ability to demonstrate proactive care and rapid response can differentiate service quality in a crowded market. When a technician arrives with a diagnostic briefing that shows a clear fault trajectory, estimated repair time, and a recommended parts list, trust is built before the first tool is touched. A shared-service approach to talent and knowledge—connecting shops with remote experts or experienced technicians for guidance—can help smaller operations meet higher standards without the burden of multimillion-dollar investments. Such platforms, designed to optimize talent matching, knowledge sharing, and workflow efficiency, have the potential to widen access to skilled labor and broaden opportunities for technicians who are seeking more stable, recognized forms of work. In this light, modernization is not merely about machinery and software; it is about cultivating a learning ecosystem where knowledge circulates as freely as parts and where every component of the repair pathway is aligned with safety, efficiency, and customer value.

For readers seeking a concrete example of how shops narrate their own modernization, consider the crossroads between imagery and practicality. A shop that embraces predictive diagnostics and remote data access can better explain to customers why a particular part needs replacement, present a data-backed forecast of performance improvements, and schedule maintenance during periods of lowest impact. Such transparency reinforces customer trust and encourages more frequent maintenance intervals, which, in turn, sustains the shop’s workflow and parts readiness. It also means technicians can trace outcomes across multiple visits, building a longitudinal understanding of a vehicle’s health rather than treating each visit as an isolated fix. The result is a more resilient business model that aligns with the expectations of a modern consumer who values speed, accuracy, and accountability.

To connect theory with practice, shops can begin by integrating diagnostic hardware with secure data protocols and by investing in a cadre of technicians who are certified in EV and HV safety practices. A gradual rollout—starting with enhanced diagnostic capabilities and telematics-enabled workflow planning, then expanding to AR-guided maintenance for complex assemblies, and finally incorporating VR-based training for ongoing skill maintenance—can yield measurable gains without overwhelming current operations. The human element remains central: technology should augment technician judgment, not replace it. When a skilled professional can harness data-driven insights and virtual guidance while still applying the tacit knowledge earned through years of hands-on work, the repair process becomes a blend of art and engineering—precise, predictable, and humane.

As this evolution unfolds, the chapter on the practicalities of shop modernization must remain grounded in the realities of a sector where informal arrangements and small-scale operations are common. The opportunity lies in designing technology-enabled workflows that are accessible, scalable, and affordable for independent shops. The promise is not a future where the technician is overwhelmed by screens, but a present where data, connectivity, and advanced training support the craft, improve safety, and elevate client trust. For practitioners, the takeaway is simple: invest in capabilities that extend vehicle life, shorten repair cycles, and deliver verifiable, data-backed service narratives. The more a shop can demonstrate control over diagnostics, parts, timing, and safety, the more it can translate technological advancements into real-world value that customers experience in a matter of hours, not days.

For further reading on structured workflow and workshop organization in this evolving environment, see the practical overview linked in this chapter: a-to-z-auto-repair. This resource offers a concise bridge between the high-level technology themes discussed here and the day-to-day decisions that determine a shop’s capability to adopt, adapt, and excel.

External resource: https://www.nhtsa.gov/technology/connected-vehicles-and-autonomous-vehicles

From Workflow to Trust: Mastering A and R Auto Repair Workshop Management

Managing a capable auto repair workshop in today’s evolving market means more than fixing engines and swapping parts. It requires orchestrating people, procedures, and performance in a way that translates skilled graft into consistent outcomes for customers, technicians, and owners. For A and R Auto Repair, this means building a durable operating rhythm that stands up to the pressures of an informal workforce, continuous technological change, and diverse customer expectations. When the fundamentals are strong, the business can scale without sacrificing safety or quality, and it can offer technicians a clear path for growth even in environments where formal employment practices are developing. The International Labour Organization’s recent overview of the vehicle repairs and services subsector underscores the scale of this challenge—nearly a hundred thousand workers in the region, with a heavy tilt toward informal arrangements and mixed employment statuses. That context makes the case for disciplined workshop management not as a luxury but as an essential engine of modernization. The real payoff is visible not only in leaner operations but in higher trust from customers and a more stable, capable workforce. In practical terms, what does this look like when put into daily action inside A and R? It starts with a decision to treat every repair bay as a small, repeatable system rather than a freewheeling, artisanal space. A standardized workflow is the backbone. It begins with a precise intake and diagnostic flow that captures vehicle history, current symptoms, and the customer’s priority. A well defined diagnostic path reduces guesswork and ensures that technicians, regardless of experience level, move through established steps toward a tested resolution. Checklists for inspections, repairs, and final quality control become universal references rather than personal habits. The payoff is measurable: fewer missed steps, less rework, and faster turnarounds. This is not about rigidity; it is about reliability. In practice, the team can map each repair in a simple sequence—diagnosis, repair plan, parts confirmation, execution, test drive, and sign off—while maintaining flexibility to accommodate unusual cases. Such standardization supports cross training, enabling junior technicians to step into tasks with confidence and safety, while senior staff can mentor with a predictable framework. The result is a consistent customer experience and a clearer development path for staff. A robust workflow also dovetails with the shop’s physical layout. Visual management and the 5S discipline—Sort, Set in Order, Shine, Standardize, Sustain—translate planning into action on the shop floor. By removing unnecessary tools and materials, the work area becomes safer and more efficient. Color coded zones and labeled storage reduce tool search times, enabling technicians to allocate their attention to the diagnostic and repair tasks that matter most. The discipline of 5S is not a cosmetic exercise; it directly affects throughput, safety, and even morale. When the space is organized, the team experiences fewer interruptions, less confusion, and a stronger sense of professional pride. The synergy between standardized workflows and a clean, navigable shop environment is a powerful signal to customers that a shop takes quality seriously and that the team operates with intention rather than improvisation. Yet the most meaningful gains come from investing in people. Continuous technician training and certification are essential as cars grow more sophisticated. Ongoing education should cover new diagnostics tools, electric vehicle systems, software updates, and new repair procedures. Training is not a one off event but a recurring investment that keeps the shop competitive and the staff confident. Certifications from recognized bodies add credibility and help technicians demonstrate their competence to customers and potential partners. Importantly, training expands the workforce’s capacity to handle complex jobs, reducing rework and improving first time fix rates. It also broadens the pool of talent available to the shop, including independent contractors who bring specialized skills. When technicians see a clear pathway for skill development, retention improves and the shop benefits from a more stable, capable team. The dialog around training should be practical and field oriented, focusing on actual diagnostics scenarios, updated repair procedures, and hands on practice with current tools. A well designed training program also addresses soft skills, such as clear communication with customers, meticulous note taking, and thorough documentation. These elements help preserve a patient, transparent service culture that customers value during every visit. A critical part of this culture is the open, transparent communication with customers about what is found, what is recommended, and why. Digital work order systems empower customers to follow progress in real time, from initial inspection notes to the final test results. A secure customer portal or app can present a clear repair plan, estimated costs, and the reasoning behind each recommendation. This transparency reduces disputes, speeds decision making, and reinforces trust. In a sector where labor arrangements are diverse, visible documentation also provides a consistent basis for accountability and professional conduct. Digital tracking extends beyond the customer relationship. It supports regulatory compliance by maintaining proper records of inspections, repairs, and test drives. The ability to reference a well documented history protects both the shop and the customer, and it contributes to a more formalized operating environment over time. The practical value of transparent communication is reinforced by performance monitoring. A small set of key performance indicators can serve as the compass for ongoing improvement. Typical metrics include average repair time, first time fix rate, customer satisfaction, and equipment utilization. Regular review meetings with team leads and frontline staff promote shared accountability and collective problem solving. When a bottleneck arises—whether in a particular bay, with a subset of technicians, or in a recurring failure mode—the team can address it quickly with targeted coaching or process adjustments. This feedback loop is the heartbeat of continuous improvement. It keeps the shop adaptable and focused on outcomes that matter to customers and to the business. Importantly, a well designed performance framework communicates value to owners and lenders, which matters to independent operators seeking capital for equipment or facility upgrades. The result is not only improved efficiency but a stronger business case for investment. The broader context of the auto repair subsector matters here as well. The ILO perspective highlights how large portions of the workforce operate informally, often in small shops with variable levels of formal registration. The best practices outlined here—standardized workflows, 5S, training, transparent communication, and KPI driven management—offer a practical bridge to formalization. They deliver measurable improvements in safety, quality, and productivity that can encourage operators to pursue formal employment practices and social protections for workers. In this sense the modernization of the sector is not a distant horizon but a set of concrete steps that small shops can implement today. The case for adoption is strengthened by platforms that ease talent access and knowledge sharing. A shared service model can connect repair shops with technicians who possess complementary skills while maintaining clear work standards and safety practices. This approach helps address talent shortages and reduces recruitment costs for businesses, all while enabling technicians to access more work opportunities within a regulated framework. It is a practical evolution of the industry that preserves the independence of small shops while expanding the professional pathways available to their workers. For practitioners who seek a concise primer on shop organization and process discipline, a reference article offers foundational steps for aligning workflows with business goals and customer expectations. See the linked resource here: A-to-Z Auto Repair. The same spirit of improvement can guide a shop toward a more formal and resilient operating model without sacrificing the local touch that defines communities served by A and R. In closing, best practices for workshop management are not merely manual tasks but a philosophy of operation. They place safety, reliability, and customer value at the center, while providing a path toward greater formalization and stability for workers in an informal economy. When these elements converge, the shop earns reliability in its repairs, trust in its conversations with customers, and a sustainable footing that supports growth and professional development for technicians. The ongoing dialogue between standardized processes, disciplined space management, continuous learning, and transparent communication will determine how effectively A and R Auto Repair translates skill into dependable service day after day. External resource note: for a deeper exploration of workshop standards and best practices, see the SAE pdf guide linked in the research results. https://www.sae.org/standards/content/ASME-AR-2026-01/

Final thoughts

A and R Auto Repair represents more than just quality service—it is an embodiment of commitment to enhancing the auto repair industry from every angle. By understanding the employment dynamics that shape our workforce, acknowledging the challenges posed by the informal economy, investing in talent development, embracing technological advancements, and adhering to management best practices, we pave the way for our continued success. We invite motorcycle and auto owners, as well as business partners in the repair ecosystem, to join us in our mission of excellence. Together, we can drive the industry toward a vibrant future.