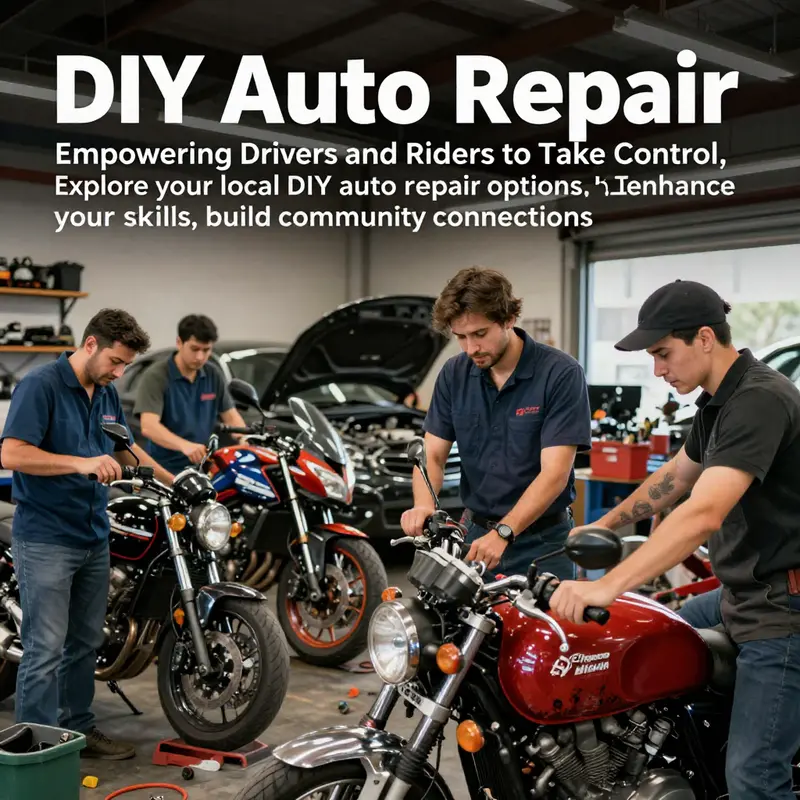

In today’s world, having the ability to perform basic auto repairs is more important than ever. Whether you own a motorcycle or a car, the significance of finding local Do It Yourself (DIY) auto repair shops cannot be overstated. These community-driven spaces not only provide the tools and environment necessary for repairs but also foster a culture of learning and independence. Understanding how to locate these resources, the benefits they bring, and the essential safety practices to follow can empower vehicle owners like never before. Moreover, engaging with your community in auto repair can lead to valuable connections that enrich your DIY experience. This article delves into the vital aspects of DIY auto repair near you, from mapping local resources to becoming a part of a supportive community.

Mapping the Local DIY Auto Repair Landscape: How to Find a Do-It-Yourself Shop Near You

Finding a do-it-yourself auto repair space near you is more than a search for a workshop. It’s about locating a place that matches your pace, your growing skill set, and the kind of support you want as you learn to diagnose, repair, and maintain your vehicle. The appeal of DIY auto work lies in the hands-on control it gives you over running costs, learning from every bolt you turn, and the satisfaction of finishing a project with your own effort. But the landscape for DIY repairs has grown more nuanced in recent years. It isn’t just about a lone garage with a set of tools anymore; it’s a tapestry of community-driven spaces, salvage-yard resources, and education-forward hubs that blend access to tools with mentorship, parts, and shared knowledge. When you begin to map these options in your city, you’re stepping into a network that supports both the novice trying to change their first brake pad and the seasoned hobbyist chasing a difficult troubleshooting challenge. The practical question, then, becomes not only where to find space but how to determine which space aligns with your goals for learning, safety, affordability, and time management. In this search, a few truths emerge that help anchor your decision. First, DIY auto repair resources near you are often tied to two distinct patterns: community-oriented workshops that emphasize shared space and learning, and parts-focused operations that provide affordable access to salvaged or second-hand components. Second, the most effective DIY spaces cultivate an environment that blends tool access with a culture of safety, advice, and accountability. Third, the best fit depends on the kind of project you’re tackling, whether you’re swapping a starter motor, refreshing the brake system, or performing routine maintenance with the patience to learn as you go. The chapters that follow stitch together practical navigation tips with clear portraits of spaces that have become touchstones for many DIY mechanics across the United States, illustrating how these resources function in real life and why they matter to you as a driver and a maker.

A practical starting point in your search is how you approach the map itself. On Google Maps, searching for terms like self-service car repair shop or community garage in your city often yields a mix of options. Some listings point to spaces that were conceived as hubs for independent mechanics, where members rent stalls or bays and bring their own tools, while others highlight facilities with a policy of hourly tool usage, shared lifts, and access to diagnostic equipment. The aim is to identify places that explicitly cater to people who want to do the work themselves rather than have a full-service shop perform the repair. If you’re unsure, call or email to confirm the current setup, hours, and what you’re allowed to bring. The world of DIY auto repair isn’t static; hours shift, tool inventories expand, and safety protocols change. A quick confirmation before you arrive can save you a lot of time and disappointment.

As you assemble a short list, think about how each space aligns with your current project scope. For a first foray, a place with a welcoming atmosphere and strong staff guidance can help you piece together a learning plan. For a project that requires a lift, air and electrical utilities, and a broader tool set, seek out spaces that explicitly advertise lift access, alignment tools, or specialty gear, while still emphasizing safety and training. This distinction matters because the right space can influence not only the quality of your repair but also your confidence level during the process. A well-chosen space acts like a mentor in hard-won ways: it nudges you toward best practices, helps you source the correct parts, and reduces the risk of mistakes that can be costly or dangerous.

In the United States, the DIY auto repair scene has matured enough to offer several recognizable patterns. There are well-regarded shops that became community anchors through a combination of extensive inventories, knowledgeable staff, and a culture that invites questions as a core part of the experience. One example is a space famed for its broad range of salvaged parts, where affordability and variety draw people who are chasing hard-to-find components for older or unusual models. A critical advantage of such venues is the ability to source parts at a fraction of new-car prices, which makes it feasible to tackle projects on tighter budgets. The trade-off, of course, is that salvaged parts require careful inspection and compatibility checks, so the space’s staff or community mentors often play a vital role in helping you assess viability and fit. The payoff is substantial for the resourceful mechanic who is willing to take the time to source parts and verify compatibility.

Another model that has gained traction is the community-driven workshop. These spaces emphasize the social and educational dimension of DIY repair. They’re designed to feel like a makerspace for cars, where enthusiasts can gather, learn, and collaborate. The appeal is not only the access to tools but also the social capital—the sense that you’re part of a community that shares wins, tries, and lessons learned. The atmosphere matters as much as the equipment, because a supportive space reduces the intimidation that often accompanies car projects. When you walk in, the staff or experienced members often help you locate the right tool, clarify safety guidelines, and discuss the safest sequence of steps for your task. Your first projects may involve more listening than turning wrenches, and that’s a healthy path to gaining confidence.

A third model is the education-forward DIY lab, a space where modern equipment meets structured learning. These centers are increasingly popular for drivers who want to deepen their understanding of how cars work, not just fix a single issue. They combine hands-on access with manuals, guided tutorials, and a culture that values the learner’s progress. In practice, this means you can come for a session on brake system basics, then move to a more advanced class on diagnosing misfires or fuel delivery issues. The blend of practical access and curated instruction is especially valuable if you’re navigating a repair that sits at the intersection of mechanical and electronic control. In these environments, the experience is less about rushing to finish a task and more about building enduring knowledge that helps you perform future repairs with greater autonomy.

These patterns aren’t mutually exclusive; many spaces blend elements of each model. In fact, the most robust local ecosystems are those that successfully marry access to tools with a culture of mentorship and a practical path for ongoing learning. Customer feedback reinforces this emphasis. Spaces that are consistently described as welcoming and knowledgeable tend to become go-to choices for DIY enthusiasts. A few recurring themes surface in reviews: a broad and well-maintained inventory, a staff that can translate repairs into approachable steps, and a community vibe that makes the work feel less solitary. When people talk about a shop as a place where they could source rare parts, or where they could turn to a patient mentor for a tricky diagnosis, you get a sense of the intangible value these spaces provide—the reassurance that you’re not alone on the repair journey.

If you’re listening to these descriptions and thinking about your own priorities, you’ll notice that the decision isn’t merely about the cheapest price or the closest location. It’s about the right balance of access, guidance, safety, and time. For a driver who enjoys learning by doing and wants to understand the “why” behind each repair, a community or education-forward space can be the most satisfying choice. For someone who is focused on getting a specific project completed quickly and cheaply, a salvage-oriented shop that helps minimize part costs might be more appropriate—provided you have the patience to verify part compatibility and quality. And for those who want a blend of learning and advanced tools, a space that offers guided tutorials alongside lift services and diagnostic equipment can be ideal.

In practical terms, locating these spaces often begins with a few simple steps. Start with a targeted map search in your city for phrases that signal self-service and community access, such as self-service car repair shop, or community garage, paired with your city name. When you find options, read the descriptions and check for explicit mentions of tools, equipment like lifts, torque wrenches, air compressors, diagnostic scanners, and safety features such as proper ventilation and fire extinguishers. Then, look for user reviews that highlight the atmosphere—whether the space fosters a helpful, low-pressure environment—and the quality of mentorship or staff guidance. The combination of tangible resources and intangible culture is what determines whether a space will empower you to tackle repairs with confidence or leave you feeling overwhelmed.

As you begin to draw a short list from your map search, you’ll encounter profiles that resemble the three models described earlier. Consider contacting the spaces directly to confirm current availability, hours, and the exact scope of services. Some might offer a pay-as-you-go arrangement, while others operate on a monthly membership that grants access to stalls, lifts, or a certain number of diagnostic sessions. A few spaces will emphasize the importance of safety training or have a waiver that outlines liability and code of conduct. While these details may seem dry, they are the practical scaffolding that makes DIY work possible and enjoyable rather than risky or frustrating. The best approach is to frame your inquiry around three questions: Do you have the necessary tools for my project? Is there staff or peer guidance available for beginners? Are there safety rules I should be aware of before I start?

For readers who want a concrete example of how this landscape can appear on the ground, consider three widely cited models that frequently surface in DIY communities. One space is celebrated for its expansive inventory of salvaged parts and its staff’s ability to source rare components at affordable prices. Enthusiasts consistently mention the breadth of options for different makes and models, along with a staff that translates part numbers into usable recommendations. A second space is praised for its community ethos: welcoming to weekend mechanics, with a culture that encourages sharing tips, a space to work, and opportunities to learn from more experienced peers. A third space emphasizes education and access to modern equipment—an environment where you can take a structured approach to learning, then apply that knowledge to real repairs with hands-on guidance.

The overarching message from this landscape is clear: the DIY auto repair ecosystem near you is a resource, not a barrier. It invites you to become a member of a community of drivers who value practical problem-solving and shared learning. The best starting point is simple curiosity—visit a few spaces, observe the flow of activity, and notice how staff and members interact with one another. Do you feel welcome when you ask a question? Do you see someone who can help you interpret a diagnosis or a parts list? Do you sense an emphasis on safety and clean, organized workspaces? If the answer is yes on these points, you may have found a space that not only supports your immediate repairs but also scales with your growing expertise.

In addition to physical spaces, a reader may wonder about the resources available to guide decisions. One practical route is to examine online guides and community-driven write-ups that distill the experiences of DIY enthusiasts. If you want more practical guidance on locating and evaluating these spaces, you can explore a dedicated DIY auto repair shop near me guide that dives into how to identify suitable venues, how to compare membership models, and how to plan your first project with a clear checklist. do-it-yourself-auto-repair-shop-near-me

Finally, it’s important to acknowledge that the landscape is dynamic. Spaces open, hours shift, and the balance between self-service and staff-assisted work evolves with demand and safety standards. Your job as a driver and learner is to stay curious, stay careful, and stay connected to the local DIY community. A productive approach is to set a short list of spaces as your initial targets, then plan a weekend to visit each one with a project in mind. If your first project is something straightforward, such as an oil change, you’ll be able to test the space’s basic tools, the reliability of the lifts, and the adequacy of the ventilation. If your project is more intricate, such as replacing a brake line or diagnosing an ignition issue, you’ll benefit from spaces that offer guided support or a mentorship-friendly environment. In either case, you’ll gain a practical sense of what works for you and what doesn’t, and you’ll build a resource network you can lean on as you expand your DIY repertoire.

As you weave through this landscape, you’ll discover that the right near-you DIY space does more than reduce costs or enable repairs. It can transform how you approach car ownership: you gain agency, a deeper understanding of your vehicle, and the confidence to tackle future maintenance with a plan rather than fear. That change in mindset is perhaps the most valuable part of mapping local resources. With time, your routine evolves from occasional weekend projects to a steady cadence of learning, testing, and refining your craft. The road from beginner repairs to more complex diagnostics is shorter when you have a friendly, well-equipped space nearby to learn and practice. And when you pair that with a culture of safety, accountability, and shared knowledge, the journey becomes not just possible but genuinely enjoyable.

For those ready to start this journey, the practical steps are simple but meaningful. Use map-based searches with city qualifiers, read up on the spaces’ stated capabilities, and listen to the stories from people who have used the spaces to complete their projects. Reach out to confirm hours and what you can bring to the bench, then plan a first project that prioritizes learning. Bring a clear plan, a parts list, and the mindset that you’re there to learn as you work. If you want to deepen the learning path, seek out spaces that combine hands-on access with educational resources, where you can incrementally expand your tool set and knowledge base. In time, your local DIY auto repair landscape will become a familiar map you navigate with confidence, guiding you through the next repair with fewer unknowns and more competence.

Internal link example for further guidance: do-it-yourself-auto-repair-shop-near-me

External resource: For an external overview of verified DIY car workshop options beyond your local listings, you can consult international sources that curate DIY spaces and share best practices for safety, equipment, and community governance. External reference: https://www.alibaba.com/showroom/diy-car-workshop.html

The Benefits of Do It Yourself Auto Repair Near Me: Cost Savings and Skills Development

Tackling car repairs close to home invites a different kind of relationship with your vehicle. It shifts maintenance from a purely transactional service to a collaborative, learning-focused activity that you control. When you search for a do it yourself auto repair space near you, you aren’t just finding a place to wrench; you’re discovering a community resource where you can grow, responsibly and on your own schedule. The idea rests on a simple premise: you can save money while building a toolkit of skills that make your daily driving safer and more predictable. This chapter traces how cost savings accumulate from small, routine tasks and how the act of doing them yourself becomes a continuous education in how your car works. It is not an invitation to turn every repair into a DIY project, but a practical argument for embracing do-it-yourself auto work as part of a broader car ownership strategy. To start, consider the most common, approachable maintenance tasks—oil changes, air filter replacements, brake pad changes, and fluid checks—that you can learn to handle with proper guidance and space. These tasks, while straightforward on the surface, unlock a fundamental truth: ongoing maintenance preserves value and performance and helps you avoid the service fees that add up quickly at a traditional shop. The economics are simple enough to understand in isolation. Professional mechanics often bill for labor at rates that can exceed a hundred dollars per visit, even for routine maintenance. When you perform these tasks yourself, you remove that labor premium from the equation. The raw cost of parts remains, of course, but you eliminate a large portion of the expense that makes a routine oil change feel like a budgetary hurdle. The math becomes especially compelling when you think about the frequency of routine maintenance. Oil changes, air filter replacements, and brake pad inspections are tasks you plan around, not emergencies you rush to fix. In a do-it-yourself setup, you can align maintenance with your calendar, not the shop’s appointment book. The savings compound over time, especially if you own an older vehicle where the compound effect of neglected maintenance might manifest as bigger, more expensive issues down the road. But the bottom line isn’t only about dollars saved per visit. The value extends into more nuanced and enduring benefits that accrue as you dedicate yourself to learning and practice. As you work on your car, you begin to read its language. The engine’s sounds, the way the steering feels on a pothole, or the cadence of a clunk when you brake—all become data points you can interpret. You cultivate a way of thinking that blends mechanical intuition with problem solving. This is skill development in the most practical sense: you gain the ability to triage issues, differentiate routine wear from more serious faults, and decide when a repair is within your capability and when it is safer to escalate to a professional. It’s a kind of self-reliance that translates beyond the driveway and into a broader confidence. You learn not to panic when a warning light flickers or a strange vibration appears. Instead, you approach the issue methodically: isolate the symptom, test a hypothesis, and confirm or refute it with simple, repeatable checks. That mindset—the habit of careful diagnosis, the discipline of documenting what you observe, and the patience to verify a fix—becomes a durable asset. In practical terms, this translates to fewer “surprise” repair bills and more predictable maintenance costs. You begin budgeting around a known set of tasks rather than reacting to whatever the shop proposed during a sudden breakdown. This consistency can be especially meaningful for long-term ownership, where the cumulative effect of small, well-timed interventions can extend the life of your vehicle and preserve its resale value. Of course, the path to these benefits requires careful planning and a well-considered approach. The first step is to find a space that supports your do-it-yourself goals. Local auto parts stores and community workshops often provide more than just parts; they can offer access to diagnostic tools, lifts, and safety equipment on a shared basis. Some spaces may also host free or low-cost classes that introduce you to fundamental repair techniques, tool usage, and best practices for working safely around a car. The value of these resources goes beyond the technique itself. They connect you with a community of fellow DIY enthusiasts who can share troubleshooting tips, safe practices, and collective wisdom born from years of hands-on experience. This social dimension matters because learning to repair a car is often as much about practicing safe habits as it is about understanding the mechanics. When you join a community workspace, you’re not isolated with just a manual and a toolbox; you’re part of a learning network that can help you avoid common beginner mistakes, such as over-torquing fasteners, mislabeling components, or neglecting fluid disposal procedures. For those who want structure, there are formal pathways that can accelerate your progress. A well-designed program will start with controlled, introductory tasks—oil changes, air filter swaps, and fluid checks—then gradually introduce more complex jobs like brake pad replacement, serpentine belt inspection, or basic electrical diagnostics. Each step builds competence and reduces risk, enabling you to expand your scope without sacrificing safety. The practical value of this approach is that you can incrementally increase your responsibilities as confidence and skill build. That incremental approach aligns with the realities of car design, where many maintenance tasks are modular and finite in scope. A simple oil change, performed with the right tools and clean technique, teaches you about the lubrication system, the oil’s role in heat management, and the importance of proper filtering. Replacing an air filter teaches you how a vehicle breathes and how clogged filters impact performance and fuel economy. Replacing brake pads, when done correctly with attention to torque specifications and proper seating of the pads, shows you the critical link between mechanical function and road safety. Each of these tasks offers tangible lessons and measurable outcomes: smoother running engines, quieter operation, better fuel efficiency, and a more confident sense of control. The learning curve, while real, is not overwhelming when you approach it with a clear plan and the right safety practices. A few guardrails help keep the learning process steady and safe. Start with the basics in a well-ventilated, well-lit space and use appropriate protective gear—gloves, eye protection, and a solid pair of footwear. Use a reliable jack and jack stands, never rely on a jack alone to support a car. Keep a clean workspace, organize fasteners and parts as you remove them, and document your steps so you can reproduce a successful repair or revert a change if something goes awry. These practices aren’t just about avoiding accidents; they reinforce the habit of meticulousness that will serve you through more ambitious tasks. When you reach for tools and information, let the process be guided by a combination of hands-on practice and curated knowledge. A helpful starting point is to consult a resource that foregrounds the basics in a practical, do-it-yourself context. For a structured primer on how to begin, explore the guide on DIY auto repair basics. This resource lays out essential concepts, tool lists, and stepwise approaches to common maintenance tasks in a way that respects safety and modular learning. It’s not about replacing professional expertise but about building a foundation that makes you more capable and informed when you do decide to bring in a professional for more complex work. The payoff for embracing this approach is not merely financial. It is the sense of ownership and responsibility that comes with caring for a vehicle you drive regularly. When you know enough to watch for wear, anticipate maintenance needs, and handle routine fixes, you are less prone to being sidelined by minor issues. You gain a more predictable driving experience, fewer disruptions to your schedule, and a level of preparedness that allows you to address future challenges with calm, not fear. It’s also worth noting that this path does not erase the value of professional service. Some repairs, due to the complexity of modern vehicle electronics, advanced safety systems, or warranty considerations, are best left to trained technicians. The goal is not to convert every repair into a DIY project but to cultivate a practical skill set that covers the maintenance spectrum—from simple checks to more involved tasks—so you can decide when to roll up your sleeves and when to call in a pro. As you continue to learn, you may find that the process becomes less about the repair itself and more about the methodology of learning. The discipline you develop—the habit of cautious planning, the practice of checking your work, and the ability to assess risk—transfers to other areas of life. The confidence you gain behind the wheel, knowing you can address the basics without external dependence, is the practical corollary to the economic savings. It’s a transformation from reactive, costly repair cycles into proactive maintenance that keeps your car reliable and your budget stable. The next step in this journey is often about access—how to find a trustworthy, well-equipped space that aligns with your goals. Look for community garages or self-service repair shops that verify their facilities and emphasize safety and instruction. A good space will offer clear safety guidelines, accessible tools, a supportive staff or mentors, and a schedule that fits your life. In a well-run DIY environment, you are guided by a culture of care: care for your car, care for your own safety, and care for the shared equipment that makes the space possible. This culture reduces the risk of mistakes and ensures that you can progress from a novice to someone who can tackle a broader range of routine tasks with confidence. Finally, the benefits you gain from diy auto repair near you extend beyond the mechanics. They feed into a broader philosophy of car ownership—one that emphasizes resilience, responsibility, and continuous learning. Your relationship with your vehicle becomes a narrative of autonomy rather than dependence, a story in which you are an informed steward of the machine that transports you through daily life. If you’re curious to see how others describe the value of DIY maintenance, you can consult broader perspectives on what aspects of car care are worth doing yourself. For a comprehensive external perspective, see: https://www.consumerreports.org/cars/diy-car-maintenance-what-s-worth-doing-yourself-a237589568/ . And if you’re seeking a structured entry point into learning, you may also want to explore the practical, beginner-friendly guidance that outlines foundational concepts and safe practices for DIY auto work, such as the resource linked here: DIY auto repair basics. These references can help you frame your early experiments and ensure you build skills on a solid, safety-conscious footing. In sum, the benefits of doing it yourself near home extend far beyond the ledger. They encompass financial prudence, experiential learning, and a sense of empowerment born from understanding the machine you rely on every day. By starting with small maintenance tasks, leveraging community resources, and embracing a steady progression, you can turn ordinary ownership into a reliable, enjoyable, and progressively self-sufficient practice. This approach aligns with a pragmatic view of car care: you manage the costs, you shape your learning, and you maintain a close, informed relationship with the vehicle that carries you through daily life.

DIY Auto Repair Near Me: Safety as Your First Tool in the Community Workshop

What draws you to the idea of doing your own car work in a nearby shop or community garage? The ability to save money, learn hands-on skills, and demystify the mechanical world can be compelling. Yet the appeal sits beside a responsibility that cannot be outsourced: safety. When you step into a space where you share tools, lifts, and space with other DIY enthusiasts, you are entering a practical classroom where the stakes are real and the margin for error is slim. The concept of do-it-yourself auto repair near me is more than a trend; it is a pathway to greater independence and confidence behind the wheel. The first question you should ask yourself before turning a wrench is not what you’ll fix, but how you’ll fix it safely. The foundation of any successful DIY repair plan is a clear commitment to safety, paired with a practical understanding of the environment you’ll work in. A community garage or self-service shop offers the advantage of access to tools and equipment you might not own at home, but it also imposes a shared responsibility to follow established safety norms. If you approach this with care, you can turn a potentially daunting task into a productive, educational, and rewarding experience.

To begin, it helps to anchor your approach in the realities of the space you’ll inhabit. A DIY repair environment is typically organized around a few core truths: you are operating on a live machine with moving parts, stored energy, and potentially hazardous fluids. You are also sharing space with others who may be working on different projects, each with their own set of hazards. The natural outcome is a culture of vigilance where everyone looks out for one another. Safety in such a setting is not about liability avoidance; it is about practical risk reduction. It means planning each step, understanding the specific demands of your vehicle and task, and respecting the limits of your own knowledge. It also means recognizing when a task is beyond your current capability and seeking guidance rather than forcing a fix that could lead to injury or further damage. As you explore DIY options near you, you’ll notice that reputable spaces emphasize a few universal principles: prepared minds, prepared spaces, and prepared procedures.

Safety considerations form a triad that holds together every successful DIY repair effort. First and foremost is battery safety. Electrical systems are a frequent source of injury, and even routine work on a car’s electrical network can produce shocks, shorts, or unintended actuations if power remains connected. The simplest rule is to disconnect the battery before you touch wires, sensors, or modules that might energize unexpectedly. When you isolate power, you reduce the risk of accidental short circuits and protect yourself and the vehicle’s sensitive electronics. The second element is vehicle support. You may be tempted to rely on a hydraulic jack alone, but that is a dangerous shortcut. If you must work underneath a car, use jack stands on a solid, level surface. Never trust a jack to bear the load by itself. A small movement of the vehicle or a shift in its center of gravity can crush or injure you in an instant. The third element is protective gear. Gloves, safety glasses, and closed-toe shoes are not cosmetic additions; they are essential defenses against hot components, sharp edges, and the unexpected flick of debris or fluids. When you’re in a community garage, you’ll often encounter residues of brake dust, oil splashes, solvents, and battery acid. Proper PPE reduces exposure and helps you maintain focus during the task at hand. The fourth element is ventilation. Some tasks release fumes that can irritate the lungs or trigger headaches. Working in a well-ventilated space or using local exhaust helps you keep air quality in a safe range, especially if you’re handling brake fluid, solvents, or coolants.

These safety considerations are not merely a checklist to glance at once and forget. They represent a habit of mind that turns every repair into a measured sequence. A practical way to embed this habit is to rehearse a simple pre-work ritual: survey the space, identify potential hazards, confirm you have the correct tool for each step, and ensure your clothing and footwear are appropriate for the job. In a community garage, where people are moving between projects, it helps to keep pathways clear, tools organized, and spill-prone fluids contained. The space itself becomes part of the safety equation. A tidy, well-lit environment reduces the likelihood of tripping over a loose wrench or misplacing a small fastener. You will learn early that the practical safety language of DIY auto work includes prioritizing stability, connectivity, and air quality over speed. Rushing to finish a repair invites mistakes; a deliberate pace, even when you are confident, is a safer path toward a solid result.

Beyond these specifics lies a broader discipline: the art of planning and verifying. Safety is most effective when it is paired with methodical practices that prevent problems before they emerge. The most reliable route is to consult the service manual for your vehicle. The manual contains the exact procedures, torque specs, and order of operations that are essential for a repair or maintenance task. A car’s systems are built with precise tolerances. When you deviate from the recommended sequence or use improvised tools, you undermine those tolerances and invite issues that last longer than the repair itself. This is especially important in tasks like brake service, suspension work, or electrical troubleshooting where incorrect torque, misaligned components, or improper torque sequences can compromise performance and safety. In a DIY context, aligning your approach with manufacturer guidance helps protect you and your vehicle’s long-term reliability, even when you’re working in a shared space.

The single greatest investment you can make early on is in the right tools and a disciplined approach to using them. Tools are not interchangeable like words in a sentence; each task requires a specific instrument to perform correctly and safely. The wrong tool can slip, damage threads, or expose you to unexpected forces. Take the time to learn which tools are essential for common tasks in your model and year. Many DIY spaces provide tool libraries or designated areas where you can rent or borrow equipment. When you gather the must-have tools, you’ll notice a difference in how you approach the job: you won’t be tempted to improvise with a mismatched wrench, and you’ll move through steps with confidence rather than improvisation. A clean, organized workspace amplifies this confidence. A tidy bench, labeled containers for small parts, and a clear plan for the sequence of operations transform a potentially chaotic scenario into a controlled and safe process. If you’re new to this environment, consider starting with a straightforward, low-risk project to build muscle memory for the routines that follow. For example, an air filter replacement, a basic fluid top-off, or a simple bulb or fuse replacement gives you a quick win while reinforcing the safe protocols that apply to more demanding tasks.

As you grow more comfortable with the mechanics of safety and the rhythm of proper technique, you will appreciate how a community workshop flavors your learning with practical, real-world constraints. Time management becomes a safety feature in itself: working within the shop’s schedule and respecting other members’ projects fosters a collaborative atmosphere where everyone benefits. The space may have specific rules about how long you can occupy a lift or how to store tools at the end of a session. These rules are not bureaucratic hurdles; they are designed to ensure that you and others can work with minimal risk and maximum efficiency. The culture you encounter in a DIY space—where questions are welcomed, guidance is available, and mistakes are treated as learning opportunities—can dramatically accelerate your hands-on growth while instilling a mature sense of responsibility for your own safety and that of others.

To connect the theory with the practical, imagine a common scenario you might tackle in a nearby DIY garage: replacing worn brake pads. It’s a mission that seems straightforward but quickly reveals the necessity of safeguards. You begin by disconnecting the battery to eliminate the chance of an electrical mishap if a sensor or actuator misbehaves during the job. You then jettison the risk of a falling vehicle by identifying solid jack stands beneath a sturdy lift point and lowering the car slowly to a stable stance. Protective gloves and glasses go on, and you ensure you’re not working with open flames or fuel vapors in the vicinity. You consult the service manual for the exact pad thickness and the correct torque for the caliper bolts. You double-check the alignment and apply a small amount of brake grease only where the manual specifies. You test the brakes only after you’ve pumped the pedal to seat the new pads and verify there is no abnormal noise or vibration. If any step feels uncertain, you pause, re-check the procedure, or seek guidance from a more experienced member or a reputable online tutorial that is specific to your vehicle’s make, model, and year. This approach demonstrates how safety and best practices translate into real outcomes: a safer repair, a more reliable result, and a stronger sense of capability that makes future projects less intimidating.

If you are new to the community workshop landscape, you may wonder how to get started with finding a nearby space that fits your needs. A practical approach is to search Google Maps for phrases such as self-service car repair shop or community garage along with your city name. This simple search can reveal verified facilities where enthusiasts and do-it-yourselfers converge to work on their vehicles with shared tools and equipment. While online directories can provide initial direction, the experience of stepping into the space is the true test of its suitability for your level of comfort, the quality of the tools, and the clarity of the safety culture. The first visit is easier when you approach it with a prepared mindset: you know the kinds of tasks you want to tackle, the safety standards you will uphold, and the specific tools you will rely on. This keeps the day focused, minimizes risk, and allows you to evaluate whether the space aligns with your goals for learning and hands-on maintenance.

For those who want to deepen their knowledge before committing to a project, a welcoming route is to tap into foundational resources that spell out the essentials of DIY auto repair. A compact, well-structured introduction can build confidence and reduce the likelihood of missteps when you actually begin a repair in a shared space. One valuable step is to explore a concise, reputable primer that outlines basics—from tool selection and workspace setup to fundamental safety practices and common pitfalls. The idea is not to replace hands-on practice but to complement it with a dependable mental model of how repairs should proceed under the constraints of a communal workshop. A useful starting point for learners is a resource that frames DIY auto repair as a blend of skill, judgment, and discipline, rather than sheer bravado or brute force. As you grow, you may want to broaden your toolkit, extend your knowledge of vehicle systems, and tackle tasks with increasing complexity. The path from curiosity to competence is paved by steady, deliberate practice carried out in a safety-forward framework.

In addition to the personal and procedural dimensions of safe DIY work, the social and procedural rhythms of a community workshop deserve mention. These spaces often host newcomers who appreciate a steady, supportive learning environment. You’ll learn how to ask for guidance without feeling like you’re burdening others, how to share space when multiple projects overlap, and how to document what you’ve done so you can revisit it later. The collective aspect is not a distraction; it is an enabling framework that reduces risk by providing immediate access to experienced perspectives, better lighting, and suitable equipment that you might not own at home. The emphasis on shared learning strengthens the practice of safety and elevates your craft. When you couple the safety-first approach with the supportive culture of a community garage, you build a durable foundation for more ambitious repairs, longer projects, and ongoing vehicle maintenance routines that can save you money and increase your confidence on the road.

If you want to anchor your learning even more deeply, you can engage with targeted, practical resources that distill the essential safety heuristics for DIY auto work. For readers who prefer a concise, task-focused orientation, a short, well-curated set of safety tips can be a reliable compass as you begin experimenting with your first repair tasks. The integration of safety into every stage of the repair—from planning and setup to execution and testing—helps ensure that your early attempts establish a habit of responsible practice rather than fear or hesitation. The goal is not to eliminate risk entirely—that would be unrealistic—but to align your actions with proven safeguards that minimize risk while maximizing learning and success. The more you practice this mindset, the more you will notice the confidence you gain when you approach a repair, diagnose a problem, or plan a maintenance session.

In closing, the concept of do-it-yourself auto repair near me is best understood as a practical journey rather than a one-off task. The journey is anchored in safety and then expanded through deliberate practice, proper tooling, and a respectful, collaborative workspace. The safety considerations—battery handling, proper vehicle support, protective gear, and ventilation—are not merely rules; they are the essential tools you wield alongside wrenches, jacks, and diagnostic devices. The best practices—consult the service manual, use the correct tools, maintain a clean workspace, and seek guidance when unsure—are not optional extras but core elements of a successful DIY program. When you pair these elements with the supportive energy of a community garage, you gain not only the ability to fix your own car but also the confidence to learn more complex tasks, repeat them safely, and share what you’ve learned with others. If you’re ready to start, tackle a low-stakes project, follow the safety playbook, and let the space around you become a classroom where every successful repair builds toward greater independence and a deeper understanding of your car. For those who want to begin with a structured primer, consider exploring foundational resources that outline DIY auto repair basics and then gradually move toward more specialized tasks as your competence grows. A well-structured approach will help you migrate from a cautious beginner to a capable, safety-conscious car owner who can handle routine maintenance, small repairs, and regular upkeep with assurance.

Internal resource to kick off the journey can be found at DIY Auto Repair Basics. This primer can reinforce the safety-first mindset while you accumulate hands-on experience in a community workshop. As you build confidence, you’ll begin to see the day-to-day work of DIY auto repair near you not as a leap into the unknown but as a measured, scalable path toward homegrown automotive competence. For readers seeking further perspective on safety and best practices in the broader DIY repair landscape, there are external resources that lay out practical guidelines and tips. External safety tips and best practices can offer a complementary viewpoint to the on-site experience you’ll gain in a community garage, helping you triangulate best practices across sources and reinforce your approach with multiple perspectives. Explore such resources to enrich your understanding while you stay grounded in the hands-on, safety-first approach that marks successful DIY auto repair endeavors.

Hands-On, Neighbor-Driven: Building Local Networks and Resources Through DIY Auto Repair Communities

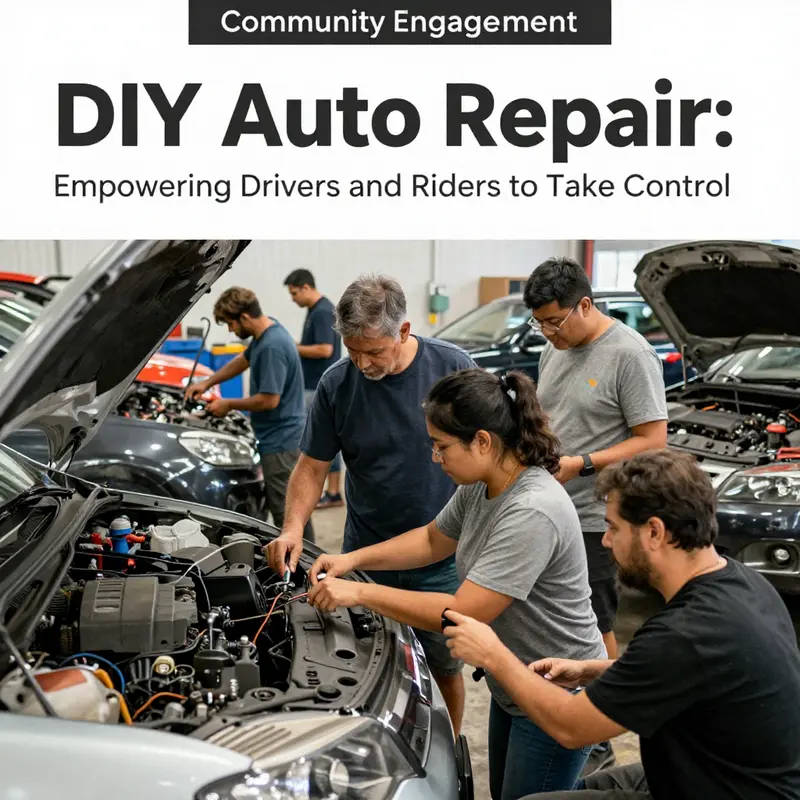

Community engagement in do-it-yourself auto repair is more than a hobby or a weekend project. It becomes a social fabric that binds neighbors through shared curiosity, practical skill, and a collective desire to keep their cars on the road with less reliance on paid services. The core idea is simple and empowering: a space where people can roll up their sleeves, borrow a wrench, tap a neighbor’s expertise, and troubleshoot together. In these small, accessible hubs, repair knowledge travels as freely as tools, and the line between learner and mentor blurs into a cooperative learning circle. The result is a network that sustains itself because its members invest in each other’s growth while taking responsibility for their own vehicles. In this way, a local DIY auto repair culture becomes a durable resource for a neighborhood, not just a service one might visit in passing.

These spaces often arise where community needs meet practical capability. A community auto repair shop is not merely a location to fix a car; it is a living workshop where people trade tips on everything from brake pads to battery health, and where a Sunday project can become a recurring class that attracts new participants every month. The atmosphere is characterized by open doors and a shared sense of purpose. Members show up with project cars, bring in spare parts found at a yard, and offer to guide a first-timer through the basics of checking fluids, reading owner manuals, or identifying a stubborn misfire. The ethos is mutual aid rather than top-down instruction. This is the heart of community-based DIY auto repair: learning that happens best when it is practical, collaborative, and anchored in local trust.

Consider Harwood Automotive, a local hub that captures this spirit. It serves as more than a repair shop; it is a social and educational center where neighbors gather to learn, exchange knowledge, and build trust through shared projects. In such spaces, conversations often begin with a mechanical hurdle and end with a plan for ongoing skill development. The shop becomes a nexus for people who want to understand their vehicles more deeply, who enjoy hands-on problem solving, and who value the resilience that comes from being able to care for their own machines. The experience at Harwood is not unusual in the sense that it is rare; it is typical in its model: a place where tools are shared, questions are welcomed, and everyone leaves a little more capable than when they arrived.

Stories like that of Donald David Philp—who was introduced to the community through his husband at this very shop—highlight how personal connections can seed larger networks. A simple introduction can become the spark that expands a neighborhood’s circle of learners, mentors, and volunteers. When people meet around engines and exhaust systems, they also meet around shared values: resourcefulness, patience, and a commitment to helping one another. Such relationships often extend beyond a single repair job. They become ongoing collaborations that help residents navigate ongoing maintenance, seasonal preparedness, and the occasional larger project that benefits the whole group, such as a community oil-change day, a volunteer-led diagnostic clinic, or a tool-swap event that keeps operating costs low for everyone involved.

The success of these networks rests on their emphasis on hands-on learning and mutual support. Individuals come to learn, but they also come to contribute. People who have built up a few repair successes become mentors, and those who are just starting out gain confidence by watching, asking questions, and trying things for themselves under supervision. In this model, the transfer of knowledge is bidirectional: experienced hobbyists refine their own understanding by teaching, while new participants gain a sense of belonging and competence. This reciprocal learning fosters a culture where curiosity is celebrated, mistakes are viewed as stepping stones, and progress is measured less by perfect outcomes and more by sustained participation. Over time, communities like these help members become more self-reliant, even when they still rely on professional services for more complex work. The objective is not to replace skilled technicians but to equip people with the autonomy to manage routine maintenance, diagnose common issues, and make informed decisions about when to seek professional help.

For readers who want to engage locally, the path often begins with curiosity and a willingness to show up. A practical first step is to locate spaces where people repair cars outside of a traditional dealership or shop setting. A straightforward search for terms like “self-service car repair shop” or “community garage” in your city can reveal verified facilities that welcome community members who want to work on their own vehicles. These spaces tend to prioritize safety, access to tools, and instruction that respects varying levels of experience. The availability of shared resources—lifts, torque wrenches, diagnostic equipment, and specialty tools—reduces the barrier to entry and makes hands-on learning feasible for a broader part of the community. While the exact model can vary, the underlying philosophy remains consistent: you gain skills, you gain confidence, and you become part of a network that supports your ongoing automotive learning journey.

Beyond the workshop floor, practical pathways to involvement extend through local networks and online communities. Platforms such as Nextdoor or Facebook groups dedicated to local mechanics and car enthusiasts often host informal meetups, tool-swaps, or volunteer-led clinics. These channels can be an excellent way to learn about events, safe practice guidelines, and opportunities to contribute your time or materials. Participation can be as simple as attending a monthly meet, asking questions about a stubborn issue, or offering to help document a repair process so others can learn from it. The social dimension of DIY auto repair is as important as the technical dimension. People come for the knowledge; they stay for the friendships, trust, and shared purpose that build stronger neighborhoods.

The values that sustain these networks—learning, collaboration, and sustainability—also align closely with broader community goals. A culture of resourcefulness supports not only individual skill development but collective resilience. Sharing tools reduces redundancy and waste, while collective problem solving makes maintenance more predictable and less intimidating. When neighbors pool their knowledge and resources, they also build a public good: a local, affordable, and accessible avenue for vehicle maintenance that can weather economic fluctuations and supply-chain disruptions. The payoff is a community that is better prepared to handle routine maintenance, minor repairs, and even occasional emergencies, all while cultivating a sense of pride in what neighbors can accomplish together.

For readers who want to take actionable steps toward involvement, there are several practical avenues to explore. Start by looking for spaces that clearly welcome DIY enthusiasts, then reach out to organizers to understand safety rules, membership or day-use policies, and the tools available. If you are looking for a starting point, a practical primer on locating a do-it-yourself auto repair shop near you can be helpful. You can read about that in more detail here: do-it-yourself-auto-repair-shop-near-me. As you learn more, consider how you can contribute. Perhaps you can mentor someone new, help facilitate a small class on basic diagnostics, or organize a tool swap to keep essential gear circulating locally.

In addition to the tangible benefits of learning and saving money, community-based DIY auto repair initiatives cultivate a culture of collaboration and sustainability that resonates deeply with neighborhoods that value resourcefulness and self-sufficiency. When people learn together, they build trust. When trust exists, it becomes the foundation for collective action—whether that action is a weekend repair party, a regular maintenance clinic, or a larger effort to maintain a community fleet of used-vehicle donations that help families get to work and school. The social outcomes, in other words, are as significant as the technical ones. The shared reliability of having a neighbor who can walk you through a stubborn sensor fault or a stubborn rust spot creates social capital that strengthens the neighborhood in ways that go beyond car maintenance.

As readers move from curiosity to participation, they should be mindful of safety, responsibility, and boundaries. DIY auto repair spaces often set clear rules about gas and fumes, the use of lifts and power tools, and the handling of hazardous materials. Respect for the space extends to documenting what you learn for others, leaving the tool area cleaner than you found it, and seeking guidance when a repair involves complex systems or requires specialized certification. The aim is to empower individuals while preserving a safe environment for everyone who uses the shop. When in doubt, seek instruction from a seasoned participant or a professional mechanic who can offer an external perspective without diminishing the value of hands-on learning.

In the long run, the most meaningful outcomes from these communities extend beyond a successful repair. They include a sense of belonging, a growth mindset, and a network of neighbors who understand that vehicle maintenance is a shared responsibility. The pride that comes from keeping a car running through self-reliant effort can ripple outward, encouraging others to take on small projects, share what they know, and participate in ongoing skill-building opportunities. The neighborhood then becomes a living classroom—where the act of fixing a car mirrors the broader work of building community, one respectful conversation, one tool, and one repaired bolt at a time.

For those seeking more information about how to engage with community-based automotive repair initiatives, the broader landscape is worth exploring. While each locale will have its own flavor, the underlying model—accessible spaces, shared resources, and a culture of collaboration—remains consistent. The experience may differ from one neighborhood to the next, but the goal is the same: empower people to be more self-reliant while strengthening the social fabric that makes a neighborhood resilient.

External resource: https://www.alibaba.com/showroom/diy-car-workshop.html

Final thoughts

In conclusion, accessing Do It Yourself auto repair resources allows motorcycle and auto owners to harness their abilities while building essential skills and community bonds. With the right tools, knowledge, and safety practices, your journey into the world of DIY auto repair can be both empowering and fulfilling. Remember, as you explore these local options, engage with fellow enthusiasts, share experiences, and continue learning. This community approach not only enriches your repair skills but also transforms the way you interact with and care for your vehicles, making the experience enjoyable and rewarding.