For motorcycle enthusiasts and automobile owners alike, finding a dependable auto repair service is essential for keeping their vehicles in top shape. AM Auto Repair, located in Glendora, California, stands out as a beacon of quality and trust. This article delves into the varied spectrum of services offered, the exceptional customer experiences, innovative technologies utilized, and the positive economic impact on the local community. As we examine AM Auto Repair’s commitment to excellence, we also look at future trends shaping the auto repair industry, ensuring you stay informed and empowered regarding your vehicle maintenance choices.

AM Auto Repair in Context: A Local Shop at the Crossroads of Craft, Regulation, and a Shifting Auto Care Economy

AM Auto Repair in Glendora sits at a quiet intersection of everyday mobility and a broader labor story that travels beyond a single storefront. It is a case study in how a neighborhood shop anchors trust, delivers technical care, and navigates licensing, regulation, and workforce organization. The shop operates on regular weekday hours from 8:00 a.m. to 5:00 p.m., Monday through Friday, and sits at 743 W Route 66, Unit 5 & 6, Glendora, CA 91740. A telephone call to (626) 963-4782 invites a conversation about repairs, scheduling, and the needs of a car, a driver, or a family dependent on reliable transportation. Nearby, AM Auto Repair Mobile LLC in Hyattsville, Maryland operates on weekdays from 8:00 a.m. to 6:00 p.m., offering on the road and at the doorstep a model of service in which technicians bring expertise directly to the vehicle. The contrast between the Glendora shop and the Hyattsville mobile operation underscores a flexible ecosystem in auto care, one that leans toward convenience and accessibility while grappling with questions about professionalism, safety, and worker protection. These macro patterns illuminate how a local shop makes everyday decisions that shape service quality and workforce stability, including the importance of clear communication, proper licensing, and adherence to safety standards. The broader economy nudges the Glendora shop toward diversification and resilience, as mobile services expand access to care and extend a technician’s reach. From the customer perspective, the value of a well run shop rests in continuity of care, transparent pricing, and clear explanations of repairs and parts. In a sector where protections can be uneven, trust is built through disciplined scheduling, accurate diagnostics, and safety protocols that support liability and warranty considerations. For readers seeking deeper context, the AM Auto Repair profile offers a bridge between local experience and the broader narrative of how small auto care businesses operate within a regulated environment while preserving flexibility. External resources like Yelp provide a window into customer experiences and standing within the Glendora community. This story highlights how neighborhood shops contribute to mobility, safety, and the local economy while navigating licensing standards and social protections for workers.

Driven by Trust: The Customer Experience That Defines AM Auto Repair in Glendora

AM Auto Repair in Glendora has built a customer experience centered on trust. Timeliness, clear communication, fair pricing, and professional, knowledgeable service form its core. Customers report diagnostics that move efficiently from problem identification to repair, with transparent quotes that match what is actually done. The result is less stress and more confidence for drivers who rely on their vehicles daily. The language used by the team is accessible, avoiding jargon while explaining what is happening and why it matters. A commitment to ongoing learning and best practices shows in the quality of work and in the results that reduce the need for repeat visits. Pricing is perceived as fair and reasonable, aligning value with expectations and giving customers a clear plan before any wrench is turned. A personal touch, including interactions with Amir, reinforces a sense of community and trust that extends beyond a single repair. Taken together, these elements create a durable relationship between AM Auto Repair and the Glendora community, turning one repair into a trusted partnership for the long term. For readers seeking additional perspectives on the customer journey in auto repair, broader industry guidance highlights the importance of clarity, competence, and care in every step of the process. You can explore such resources to understand how great shops structure intake, diagnosis, planning, and execution, and how drivers can look for honesty and transparency in quotes.

Precision, Pixels, and Parts on Demand: Technical Innovations Reshaping AM Auto Repair

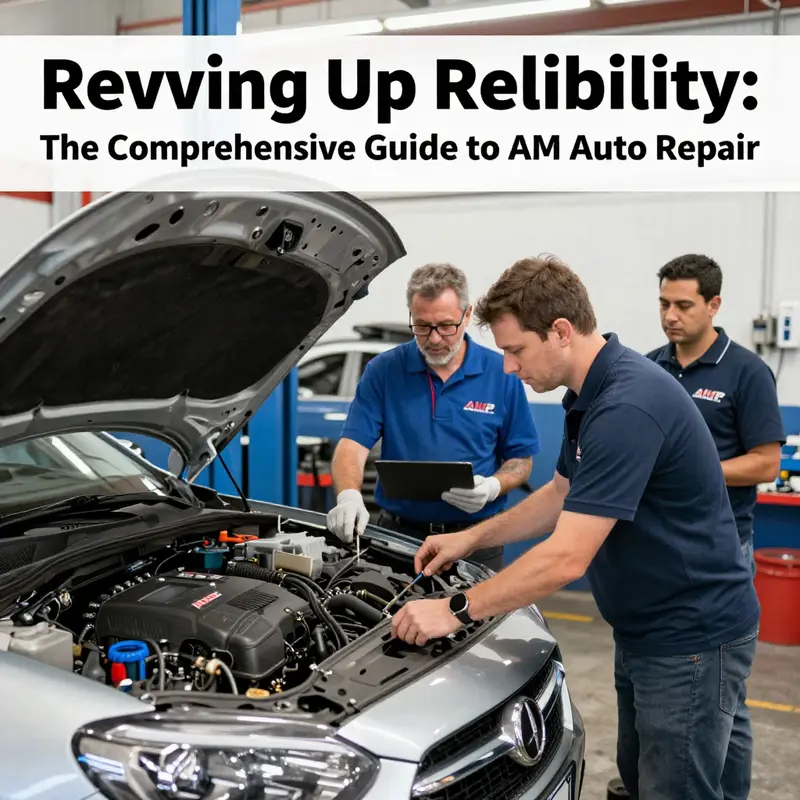

AM Auto Repair in Glendora sits at the crossroads of craft and code, where decades of hands-on know-how meet a rising chorus of diagnostic dashboards, data streams, and on-demand fabrication. The shop, tucked along a familiar California corridor, operates with the cadence of a traditional local business while quietly integrating the tools that are reshaping the entire automotive service ecosystem. The technicians understand that the modern vehicle is no longer a collection of discrete components but a networked system whose health is best assessed through holistic insight. In that environment, the workbench becomes a cockpit for exploration, where sensors, software, and skilled hands collaborate to translate complex signals into reliable, repeatable repairs. This fusion of skill and technology is not a distant dream but a daily practice that keeps customers safe, satisfied, and on the road longer than before.

The most noticeable shift begins with diagnostic and testing capabilities that go far beyond the standard code reader. Today’s high-stakes diagnostics traverse the vehicle’s myriad control modules, battery architecture, and thermal management, especially for electric and hybrid configurations. A comprehensive testing approach maps every layer of energy flow, temperature, and charging behavior, delivering a clear picture of how a vehicle behaves in the real world. At the same time, technicians perform high-precision calibration for driver-assistance features, ensuring that cameras and radar sensors respond accurately in varied lighting and weather. The goal is not merely to fix a fault but to restore the integrity of perception and decision-making systems that modern drivers rely on for safety. This requires meticulous data interpretation, validated test procedures, and a disciplined hand for reassembly that preserves the vehicle’s original performance envelope.

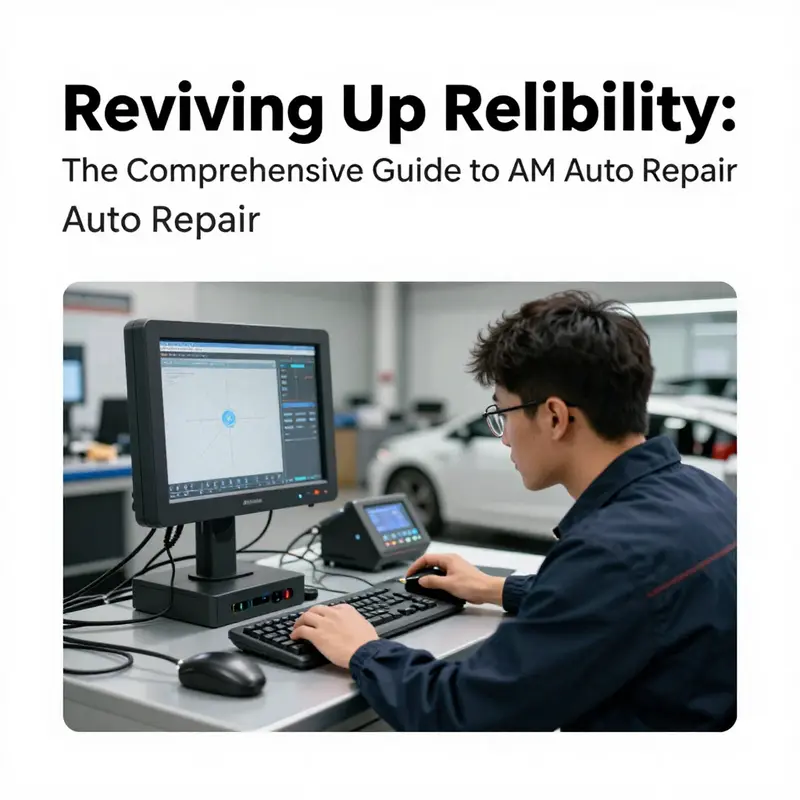

Digitalization threads through every corner of the operation, turning a busy shop floor into a connected, intelligent workspace. Real-time data from vehicles in service is collected and securely transmitted to a centralized system where history, fault patterns, and service notes can be compared across cases. Technicians use smart workshop platforms that coordinate job orders, parts availability, and repair instructions, eliminating duplications and inefficiencies that once slowed progress. The workflow becomes a living document, evolving as new information comes in and as technicians grow more confident in predictive trends rather than reactive fixes. With digital tools, a customer’s car does not simply move from A to B; it travels through a transparent, auditable process that maps out why a repair was chosen, how it was executed, and what outcomes are expected in the weeks ahead. The improvement is tangible: shorter turnaround times, fewer unexpected callbacks, and a customer experience that feels informed rather than opaque.

Among the most compelling shifts is the embrace of innovative repair methods that redefine what is possible when design and manufacturing principles meet the workshop. Additive manufacturing, commonly known as 3D printing, enables rapid prototyping and the creation of custom or hard-to-source parts. In practice, when a part is scarce or discontinued, technicians can scan a component, reverse engineer it, and print a matching replacement with exact tolerances. The result is a repair cycle that moves with greater velocity, reduces inventory pressures, and opens opportunities for customization where needed. Printing can be paired with high-precision scanning to verify fit in real time, turning what used to be a gamble into a controlled, repeatable process. The concept of print-and-go production—where an on-site fabrication step supports the repair workflow—demonstrates how the shop can adapt to the evolving parts landscape without sacrificing accuracy or reliability.

Finishing and coatings have not been left behind in this technological arc. Finishing systems have matured to emphasize uniform atomization, controlled airflow, and consistent curing. A reliable, repeatable painting process translates into a durable, aesthetically consistent result across a wide range of panels and shapes. The technology behind modern spray systems is designed to minimize overspray, reduce defects, and reproduce factory-quality appearances that endure under sun and weather. For customers, that means not only a seamless repair from a functional standpoint but a long-lasting finish that maintains color consistency and protection against the elements. The emphasis on quality at every stage—from diagnostics to the final coat—reflects a broader commitment to value and durability that customers can measure in months and years rather than weeks.

Safety and sustainability thread through every aspect of the operation and influence decisions from workflow design to material choice. NVH, or noise, vibration, and harshness, has grown from a comfort feature into a measurable target for quality and longevity. Modern testing paradigms capture how a vehicle behaves across routes, loads, and environmental conditions, guiding technicians to tune components for quieter, smoother operation. In parallel, there is a concerted effort to improve powertrain efficiency and durability, particularly for fleets that bear heavy daily loads. This is not about chasing the latest gadgetry for its own sake; it is about aligning practice with the reality that more efficient, more reliable propulsion reduces operating costs and environmental impact. The outcome is a service model that respects both the immediate safety of each repair and the long-term resilience of the vehicle across its useful life.

The Glendora workshop’s approach also signals a broader industry move toward data-informed decision making and speed without sacrificing craftsmanship. The shift from a purely craftsman-centric ethos to a hybrid model—where expertise is enhanced by digital tools—offers customers a predictability that was rare a generation ago. A clear, data-driven timeline, visible through a transparent repair plan, has become a hallmark of the customer relationship. Likewise, dashboards that translate technical details into plain-language explanations help owners understand why a fix is recommended and how it affects future reliability. This transparency strengthens trust, and trust is a currency that sustains repeat business and referrals in a competitive landscape. It is not about replacing the human touch; it is about amplifying it with data, standards, and repeatable processes that make mastery scalable.

The practical implications extend beyond the four walls of the shop. The AM Auto Repair family, with its related mobile service option, demonstrates how the same standards of diagnostic rigor, repair precision, and finishing excellence can be delivered on-site. Bringing the workshop’s ethos to a client’s driveway or workplace requires the same discipline of data capture, remote collaboration, and quality control. Mobility adds convenience for customers and efficiency for fleets, while preserving the integrity of the repair process. It is a natural evolution in a world where time is a critical resource and where customers expect not only speed but certainty that the job was done right the first time. The integration of mobile service possibilities with a centralized, technically proficient shop model also invites a broader conversation about workforce development, training, and the logistics of maintaining consistent quality across dispersed teams.

For readers seeking a deeper connection between local practice and global trends, consider how industry platforms are converging with AI, automation, and digitalization in aftermarket ecosystems. The horizon features increasingly intelligent service models, where data from countless vehicles informs predictive maintenance, parts optimization, and remote coaching. In practice, this means better uptime for customers and steadier workloads for technicians, a virtuous loop that sustains quality while pushing for efficiency. The Glendora operation stands as a microcosm of that movement, showing how careful blending of craft and code can deliver results that feel both familiar and futuristic. If you are curious about how innovation translates into day-to-day service, see the short link embedded here: a-m-auto-repair.

Looking ahead, the automotive repair landscape will continue to evolve with the same spirit that has pushed AM Auto Repair forward. The integration of holistic testing, precise alignment, agile fabrication, and refined finishes will become more standardized across shops of similar size and scope. Customers will experience shorter waits, fewer surprises, and better outcomes. Technicians will access more information, more options, and more feedback loops to improve every repair. The broader ecosystem—suppliers, manufacturers, training bodies, and regulatory frameworks—will reinforce this trajectory with higher expectations for safety, accountability, and environmental stewardship. The result is a healthier, more sustainable, and more capable industry that can handle the evolving complexity of modern vehicles, whether in a small California town or a metropolitan corridor. The path forward is not a single invention but a continual layering of tools, processes, and relationships that keep people moving with confidence.

As a final note of context, the chapter acknowledges that real change occurs where people trust the tools and systems as much as they trust the hands that apply them. The shop’s ability to pair hands-on calibration with digital traceability demonstrates a model others can adapt. It is not simply about adopting the latest gadgetry; it is about ensuring that every improvement yields one clear benefit for the customer: confidence. When a driver leaves a repair facility, they should feel assured that the vehicle is safer, more reliable, and better prepared to deliver the experiences they expect on the road. The combination of high-tech testing, smart scheduling, and careful finishing makes that assurance tangible, not theoretical.

For researchers and practitioners exploring the macro-trend, a bigger picture emerges. The aftermarket is becoming a converged space where software-driven diagnostics, data-sharing platforms, and additive manufacturing coexist with skilled hands. The result is a more resilient, cost-efficient, and customer-focused service model. The Glendora operation is one of many signals that this transformation is not hypothetical but actively shaping the daily work of technicians, store managers, and shop owners alike. It invites a broader curiosity about how the next generation of vehicles will influence the repair ecosystem, from training curricula to standard operating procedures and to the customer dialogues that accompany every service call.

Finally, to connect local practice with the global stage, note that industry showcases and exhibitions are increasingly vital. They provide a platform for suppliers, service providers, and repair shops to exchange ideas, testifying to a shared commitment to safer mobility and responsible stewardship of resources. The forthcoming exhibitions will highlight AI-assisted diagnostics, platform-enabled workflows, and sustainable repair practices that keep vehicles safer, longer. In that sense, AM Auto Repair in Glendora stands as a living example of how a small business can become a node in a much larger network of innovation, collaboration, and continuous learning. External resources are available online to illuminate these trends, inviting readers to explore beyond the local horizon: AMR China Exhibition.

Wheels of Resilience: The Local Economic Footprint of a Neighborhood Auto Repair Hub

In Glendora, California, a modest auto repair shop sits along a busy corridor, quietly anchoring a network of everyday activities that keep the town moving. It opens its doors each weekday at eight and closes at five, a predictable rhythm that mirrors the workdays of residents who rely on reliable transportation to reach jobs, schools, clinics, and markets. This chapter looks beyond oil pans and tune ups to examine how a single, well placed service provider in a small city can become a meaningful force in local prosperity. The economy of a place is not simply a ledger of profits and taxes; it is the lived experience of mobility, opportunity, and trust. When a shop keeps cars on the road, it also keeps the local economy moving.

Direct employment forms the most obvious thread tying a local repair shop to the community. The technicians who diagnose engine trouble, replace brakes, or recalibrate sensors are skilled tradespeople whose careers depend on stable demand for their craft. Behind them are service advisors who translate technical details into understandable plans for customers, and administrative staff who manage appointments, warranties, and records. In many communities, these roles offer more than a paycheck: they provide pathways to advancement, professional development, and economic stability for families. A shop of modest size can still present a reasonable employment footprint, and as demand grows—through rising car ownership, aging fleets, or increased emphasis on safety and compliance—the hiring impulse expands along with it. The ripple effect is not confined to the shop walls; the wages earned by these workers circulating locally become part of a multiplier process. Local households spend on groceries, housing, and services, supporting other businesses and reinforcing a resilient local wage base. In this sense, the shop is a node in a regional network where each job creates opportunities for the next.

But the economic footprint extends far beyond payroll. Auto repair shops operate within a wider supply chain that links them to regional distributors, wholesalers, and manufacturers of parts, tools, and diagnostic equipment. Every brake pad, spark plug, or set of rotors purchased from nearby suppliers represents a small but cumulative contribution to the regional economy. Small businesses that supply hardware, shop fittings, cleaning services, and office supplies benefit from the sustained demand associated with a steady service stream. Local logistics and transportation firms often collaborate with the shop to manage timely deliveries of parts and tires, a service that, in turn, supports reliability for local fleets—from landscapers to plumbing contractors to delivery services. This is a classic example of a localized economic circle: the shop buys locally, pays local workers, and those workers fuel other local purchases, creating a multiplier effect that reverberates through the town’s commercial landscape. The evidence of such ripple effects is visible in the way a neighborhood repair shop becomes a dependable client for a network of nearby businesses and tradespeople, reinforcing business confidence and enabling smoother operations across adjacent sectors.

A neighborhood auto shop also functions as a community platform, contributing to social capital in practical, measurable ways. Local repair centers often participate in neighborhood events, sponsor youth teams or school programs, and support charitable initiatives. While these actions may seem peripheral to the primary business, they strengthen trust and legitimacy within the community. Trust is a resource as tangible as any inventory of parts; it reduces transaction costs, encourages repeat visits, and fosters long-term customer relationships. When residents believe in the integrity and reliability of a local shop, they are more likely to bring vehicles back for routine maintenance, refer friends and family, and choose local services over distant, impersonal alternatives. That preference is not merely sentiment; it translates into sustained demand that stabilizes revenue, preserves jobs, and keeps tax revenues within the community.

The economics of such a shop cannot be understood without acknowledging the broader context in which repair services operate. The service and repair segment plays a crucial role in sustaining vehicle use and supporting economic continuity, even as the share of motor vehicle manufacturing in the economy shifts over time. A landmark perspective from industry insights underscores that while manufacturing’s share of value-added in the economy has declined since the mid twentieth century, the service and repair sector remains robust and essential to urban and rural life. This chapter returns to that insight, translating it into a local frame: when a shop keeps cars roadworthy, it enables people to maintain employment, access healthcare, and participate in commerce. The maintenance of mobility is not a luxury; it is a foundational pillar of daily economic functioning.

In many ways, the local auto repair shop is a practical embodiment of economic resilience. It demonstrates how a single business can anchor a cluster of activities—employment, supplier relationships, maintenance of infrastructure, and community trust—that collectively sustain a local economy through fluctuations in consumer demand, shifts in vehicle technology, and the pressures of online competition. The rise of online platforms and nationwide service centers has presented challenges to local shops, particularly in attracting a steady flow of customers for routine maintenance. Yet the same forces that pressure small operators can also reinforce the advantages of staying local. When residents choose a neighborhood shop for routine services, they are choosing not only convenience but also accountability, personalized service, and a trust that is often hard to replicate at a distance. Local businesses, by necessity, cultivate reputations built on reliability and a track record of safe, timely work. That reputational capital translates into a more predictable revenue stream and a greater likelihood of reinvestment in equipment, staff training, and facility improvements.

The economic story of a single shop, therefore, is not about isolated numbers; it is about a network of relationships—between employer and employee, between the shop and regional suppliers, between the business and the families who rely on it. The stability of this network matters during downturns as well as upswing periods. When the local economy experiences stress—say a downturn in a nearby manufacturing plant or increased fuel costs—the ability of residents to access affordable, dependable car maintenance can preserve mobility, reducing missed workdays and facilitating recovery. In this way, the shop contributes to social and economic resilience by acting as a reliable, local node within a larger system. The interdependence is evident in the careful balance the shop maintains: competitive wages to attract skilled technicians, fair pricing that reflects the community’s realities, and ongoing investments in diagnostic equipment and safety training to keep pace with evolving vehicle technology. Each of these elements supports a stable workforce and, by extension, a stable local economy.

To imagine the full scope of this impact, consider not just the shop’s payroll or its immediate purchases, but also the extended footprint of its activities. A technician who learns a new diagnostic technique may mentor a junior mechanic, creating a lineage of knowledge that keeps the business—and the community—up to date with high standards of service. A salesperson may cultivate relationships with fleet operators in the surrounding area, turning a steady stream of maintenance work into predictable revenue. Administrative staff handling insurance claims, warranties, and customer records contribute to the local economy by maintaining the flow of commerce and ensuring that funds circulate efficiently. The cumulative effect is a resilient ecosystem where mobility, employment, and local spending reinforce one another, even when national signals point in a different direction.

Beyond the Wrench: How Future Trends Will Redefine AM Auto Repair

AM Auto Repair sits at the edge of tradition and technology in Glendora, a place where the routine rhythms of oil changes and brake inspections now share the floor with dashboards awash in data and firmware updates. The shop’s hours—opening at 8:00 AM and closing at 5:00 PM on weekdays—remain a constant, but the work occurring within those walls is increasingly informed by a broader, more connected automotive world. Modern vehicles are not just mechanical systems; they are distributed computers that talk to one another, to owners, and to the repair ecosystem itself. Cars now arrive with a map of their health, a tapestry of sensor readings, and a trail of digital footprints that trace every warning light and every calibration. For a neighborhood like Glendora, this shift is both a challenge and an opportunity, the chance to provide faster, more precise service while also elevating the level of trust customers place in a local shop. The same reality is unfolding in repair markets everywhere, and the lesson for AM Auto Repair is simple: adapt in step with the car, or risk becoming a roadside afterthought. Acknowledging that, the shop becomes a node in a larger digital network, where real-time data and remote insights begin to influence every decision from scheduling to parts sourcing to the moment the hood is reopened.

As a consequence, the everyday language of auto repair is changing. Technicians speak of IoT ecosystems, not just wrenches and torque specs. They refer to ADAS—advanced driver-assistance systems—as a core category of service need rather than a buzzword. They discuss software-driven diagnostics with the same seriousness once reserved for the engine’s physical internals. This evolution means that a visit to AM Auto Repair may begin with an unfamiliar, softly blinking alert on a dash and end with a careful explanation of what the data implies about a vehicle’s next miles on the road. The technician’s toolkit is no longer limited to a set of hand tools and a diagnostic wrench; it includes code readers, secure data interfaces, and calibration fixtures designed to align sensors with the precision that today’s electronics demand.

The integration of advanced technologies is reshaping the demand for skills in the AM Auto Repair ecosystem as surely as it reshapes customers’ expectations. Electric propulsion systems, while popular for their efficiency and performance, introduce a different set of service concerns. The high-voltage environment, battery management strategies, and powertrain electronics require a disciplined approach to safety, estimation of remaining life, and safe disassembly and reassembly practices. In this context, the shop must invest in training that blends hands-on mechanical work with software diagnostics, cybersecurity hygiene, and a working familiarity with data streams that originate in the vehicle itself and travel to cloud-based analysis. The shift is not a temporary trend but a structural change in what it means to service a modern car. It also means a broader pool of talent is sought, from technicians who specialize in ECUs to those who calibrate sensors with nanometer precision and verify OTA (over-the-air) updates as seamlessly as a software patch is installed on a smartphone. The consequence is clear: fewer misdiagnoses, faster turnaround times, and more reliable outcomes that customers can verify through transparent explanations and test drives.

This transition, however, does not occur in a vacuum. It is reinforced by the growing role of predictive maintenance, which relies on AI-driven analysis of real-time sensor data to forecast failure before it happens. The practical promise is simple and powerful: minimize downtime by addressing issues while they are still latent, optimize maintenance windows to align with a driver’s schedule, and extend the life of components through timely interventions. For AM Auto Repair, predictive maintenance translates into proactive outreach—reminders tailored to the owner’s driving patterns, climate exposure, and maintenance history. It also means a new cadence of visits that can be scheduled with precision, rather than the traditional, reactive model that has long defined the industry. The business benefit is equally tangible: steadier workflow, higher utilization of diagnostic tools, and greater customer satisfaction when vehicles stay on the road longer with fewer unplanned interruptions. An important dimension of this approach is the personalization of maintenance plans. Rather than a one-size-fits-all interval, plans are calibrated to a driver’s habits, geographic conditions, and even the typical load on the vehicle. This is not mere segmentation; it is a shift toward a relationship where service becomes a predictable, value-adding partnership. The concept links back to the foundational idea that an AM Auto Repair shop is more than a shop floor—it’s a data-enabled service platform that complements the garage’s physical expertise with digital intelligence. To see how one local shop is framing this evolution, consider the case of the A-M Auto Repair page, which outlines a willingness to integrate new tools and training as part of daily operations. A-M Auto Repair.

In practice, the adoption of these capabilities is inseparable from the ongoing rise of electrified vehicles and the broader push toward more connected mobility. EVs not only demand new training in high-voltage safety and battery management but also invite a rethinking of parts availability, service scheduling, and workshop layout. The battery packs, power electronics, and thermal management systems require specialized equipment and procedures that differ substantially from traditional internal combustion engine work. Consequently, repair shops must not only hire technicians with the right skill sets but also reorganize workspaces to accommodate safe handling of high-voltage systems and the equipment needed for precise battery diagnostics. This reorganization often means investing in dedicated safety protocols, enhanced ventilation, and clear, auditable processes that reassure customers about the safety and quality of the service. It also means forging relationships with suppliers and training partners who can provide the latest knowledge and tools, so the shop stays current with evolving standards and best practices. In this sense, the future is as much about culture as it is about technology: a culture of continuous learning, rigorous process discipline, and a commitment to transparency that customers can feel when they walk through the door.

As the workforce evolves, the repair shop’s diagnostic capabilities become increasingly data-driven. Diagnostic tools must be capable of interfacing with a vehicle’s digital architecture, reading complex fault codes, and interpreting sensor data in the context of a given driver and environment. This requires ongoing upskilling across the team, from technicians who can interpret a graph of an energy management system to a service advisor who can translate technical data into practical maintenance recommendations. The broader shift toward AI-assisted diagnostics also introduces new expectations about accuracy and speed. With AI analyzing patterns across thousands of vehicles, legitimate issues may be flagged more quickly, while technicians still perform the crucial hands-on verification that ensures safety and reliability. The balance between machine-driven insight and human judgment becomes a central principle in the shop’s operating model, enabling a more efficient triage process and reducing miscommunication with customers about the nature of a fault and its remediation.

From a customer’s perspective, this evolution promises a more personalized, transparent, and predictable service experience. Technology enables better timing for maintenance based on how a car is actually used, where it is driven, and under what weather conditions. Instead of generic intervals, owners can receive reminders that reflect their unique situation, followed by a clearly explained plan for the next service that aligns with real-world usage. In parallel, digital interaction tools—like secure online scheduling, real-time status updates, and digital invoices—become standard expectations rather than exceptions. The shop becomes a trusted advisor, guiding owners through data-rich conversations about a vehicle’s health rather than delivering a single, static service event. These changes, when implemented with care for privacy and security, reinforce the value of the local garage in an increasingly digital world. The goal is not to replace human expertise but to augment it with technology in a way that preserves trust, reduces downtime, and makes vehicle ownership easier and more reliable.

The broader implication for AM Auto Repair and similar shops is a necessity to invest wisely in people and tools. Upskilling programs, appropriate diagnostic hardware, and secure data practices are no longer optional add-ons; they are core to maintaining competitiveness as the vehicle fleet becomes smarter. Financial considerations follow naturally: while upfront investments in training, equipment, and workspace redesign can be substantial, the long-term returns—lower repair times, higher first-visit accuracy, and happier customers who return for routine service—are compelling. In a market where customers increasingly compare digital experiences alongside technical proficiency, the ability to deliver quick, precise, and communicative service can become a defining differentiator for a neighborhood shop. The path forward involves strategic planning that aligns with the realities of local demand, the pace of regulatory and safety changes, and the evolving ecosystem of service providers, technicians, and data security partners.

In this light, the future of the auto repair industry is less about resisting change and more about orchestrating a smart, connected service experience. Shops that actively pursue upskilling, adopt interoperable diagnostic platforms, and embrace AI-informed maintenance will find it possible to shorten downtime and improve reliability for the vehicles that keep communities moving. The promise is not theoretical; it is practical, repeatable, and scalable, with a direct line from the customer’s driveway to the repair bay. The ultimate measure of success will be the shop’s ability to translate data into confidence—confidence that a vehicle is safe, that maintenance aligns with real driving, and that owners understand what is being done and why. In Glendora and beyond, the companies that master this language will become indispensable partners in daily mobility, turning complex systems into understandable services and helping people stay on the road with less disruption. For those seeking a broader horizon, external insights on how these trends are shaping the industry can be found in leading analyses such as this Forbes piece on automotive industry trends and predictions: https://www.forbes.com/sites/forbestechcouncil/2024/05/15/driving-the-future-10-automotive-industry-trends-and-predictions/.

Final thoughts

In conclusion, AM Auto Repair is more than just a service provider; it embodies a commitment to quality, community engagement, and forward-thinking innovation. Vehicle owners can rely on their expertise to enhance performance, safety, and longevity. Furthermore, the local economic contribution cannot be understated, as AM Auto Repair not only serves its customers but also enriches the community as a whole. As the automotive landscape evolves, staying informed about trends and services at AM Auto Repair ensures that your ride remains a source of pride and reliability.