Auto repair has evolved from a hands-on craft to a data-driven, tech-enabled ecosystem that touches riders, drivers, retailers, and service centers alike. A to Z Auto Repair captures this entire landscape, from the moment a customer reports a symptom to the final road test after a calibration, and it does so with a view that crosses motorcycles and automobiles, independent shops and dealership service bays, and both local and wholesale supply channels. In a world where vehicles increasingly rely on software, sensors, and connectivity, diagnostic accuracy, process discipline, and transparent communication are not optional – they’re the foundations of safety, reliability, and trust. This article threads five core dimensions into a cohesive picture: how diagnostic workflows are built on robust data and testing, how a shop’s toolkit and layout unlock efficiency, how economics and labor dynamics shape pricing and throughput, how the regulatory and environmental context sets boundaries and opportunities, and how societal expectations around transparency, sustainability, and service quality are reshaping every interaction. Each chapter connects back to A to Z Auto Repair as a unified concept—a spectrum that spans the garage floor, the parts shelf, and the digital tools that guide modern care. Whether you’re a motorcycle owner seeking dependable maintenance, an auto owner pursuing predictability and value, a parts distributor aiming for reliable compatibility, or a repair shop aiming to deliver safer, faster service, the same principles apply: diagnose correctly, equip wisely, price fairly, comply rigorously, and put the customer experience first. The journey ahead outlines not just what to do, but why it matters and how to execute it for real-world outcomes.

From Signals to Solutions: The Technological Foundations and Diagnostic Workflows Powering A to Z Auto Repair

Every modern vehicle is a moving network of sensors, controllers, and software that speaks a language of voltages, codes, and command sequences. In the end, the repair shop acts as a translator, translating a jumble of data into decisions about parts, procedures, and timing. The chapter you are about to read traces the core technologies that make this translation possible and follows the diagnostic workflow that turns patient symptoms into safe, reliable road service. It is a story of hardware and software co-dependence, of data integrity, and of careful, execution-focused processes that keep vehicles safe as they ride a rapid curve of technological change. At its heart lies a simple truth: diagnostic mastery comes from understanding how information travels inside the vehicle and how service workflows bend that information toward repair in a predictable, traceable way.

The technological foundations begin with a layered architecture of electronic control units, sensors, and actuators distributed throughout the vehicle. Each module operates as a tiny computational node, collecting data from its own internal state and from the chassis around it. Communication networks, ranging from well-established legacy buses to newer high-bandwidth links, carry the signals that coordinate engine control, braking, climate, and occupant safety. Reading fault codes, real-time sensor streams, and event memories requires access to these networks through standardized interfaces and vehicle-specific connectors. The result is a standardized yet highly diverse data environment in which diagnostic tools must operate. This is where the technician’s toolkit expands beyond a simple wrench into a suite of software-enabled capabilities: OEM-grade diagnostic platforms, pass-through interfaces, and cloud-connected services that provide guided repair procedures, calibration data, and software updates.

The diagnostic workflow itself unfolds in a disciplined sequence. First comes data acquisition: technicians pull fault codes from onboard systems, then supplement those codes with live data streams, freeze-frame information, and historical logs. The diagnostic narrative turns on symptom triangulation—mapping a customer-reported drivability issue, warning light, or unusual behavior to the most plausible failure modes. This step relies on access to a broad knowledge base, including wiring diagrams, service information, and reference values for sensors and actuators. When codes point to a likely culprit, the process progresses to active testing. Bidirectional control, electrical measurements, circuit tracing, and waveform analysis provide the proof needed to confirm or refute a hypothesis. An oscilloscope may reveal a misaligned sensor signal, while a relay test uncovers a grounding fault or a harness issue. Precision is essential; a single bad waveform can mislead the investigation, causing unnecessary part replacement or misdiagnosis.

Component replacement and reinitialization then follow, with attention to compatibility and learning procedures. Modern ECUs frequently require re-learn sequences, calibration runs, or software reflash to reestablish proper behavior after replacement. The calibration activity is not optional ornamentation; it is literally the bridge between a repaired component and a vehicle that can operate safely under real-world conditions. After a repair, verification becomes the final gatekeeper of quality: a test drive, functional checks, and data logging must confirm that the driving experience matches the manufacturer’s specifications and the customer’s expectations. This verification loop is a critical quality control step, ensuring that success is defined not by the act of replacing a component but by the end-to-end restoration of normal operation.

Several technologies shape this workflow and define the capabilities of a capable shop. On-board diagnostics and modern CAN bus data access provide the backbone of standardized fault reporting, enabling rapid triage and cross-ECU verification. Diagnostic software platforms synthesize OEM service information with aftermarket databases, creating a guided repair path that integrates calibration data and cloud-based updates. Advanced measurement tools—oscilloscopes for waveform capture, precision digital multimeters, and specialized probes—allow technicians to quantify electrical behavior and locate issues that are not immediately visible. For those working with electrified powertrains, high-voltage safety equipment and infrared thermography expand the diagnostic envelope to thermal and electrical domains that were previously inaccessible. Calibration and reprogramming are now routine in many repairs, requiring tool licenses, access to vehicle software repositories, and careful adherence to reinitialization routines so that updated parameters, learned behaviors, and adaptive strategies align with the vehicle’s expectations.

Another cornerstone is the increasing emphasis on sensor-based alignment and calibration for advanced driver-assistance systems. ADAS work is not purely mechanical; it demands precise target alignment, sensor calibration, and sometimes external test environments to validate performance. This introduces a new layer of procedural rigor to the repair process. The operational side of diagnostics also evolves with shifts in data security and privacy concerns. As vehicles become more connected, shops must protect sensitive customer data and ensure that diagnostic interfaces remain secure against unauthorized access, while still delivering fast, reliable service. Warranty considerations and service history integrity require disciplined documentation and traceability: digital inspections and photo records are more than convenience; they are a record of due diligence.

In practice, the diagnostic workflow is rarely an isolated sequence. It integrates with shop operations and customer interactions in ways that matter to the bottom line and to trust. Digital vehicle processing—online estimates, electronic work orders, and digital inspections—transforms what customers expect from a service experience. Instead of a vague promise, customers receive a transparent, data-driven narrative of the health of their vehicle. The tradeoffs are real: the tools and platforms that enable this transparency require ongoing investment, and the data generated by each job must be managed to deliver value while protecting privacy.

Looking ahead, the field continues to be shaped by trends that blur the line between diagnostic work and predictive maintenance. AI-assisted diagnostics can surface patterns across thousands of microcases, offering probabilistic pathways that help technicians decide where to focus their tests. Cloud-based diagnostics and remote support extend expertise beyond the shop floor, enabling faster triage for complex cases. OTA updates, while offering tremendous convenience for software-driven improvements, introduce cyber risk and the need for robust cybersecurity practices. The notion of a digital twin—an evolving model of a vehicle’s behavior tracked across service events—offers a compelling vision for proactive maintenance, where anomalies can be flagged before symptoms become noticeable in daily driving.

Interwoven with these technical threads is the human factor: technicians who continually update their skills through formal certifications, apprenticeships, and hands-on practice. The labor dynamic remains central to the health of the ecosystem; a technician’s ability to interpret data, perform precise measurements, and execute complex procedures is not replaced by automation but enhanced by it. The shop that thrives in this environment pairs disciplined processes with a culture of continuous learning, ensuring that the diagnostic workflow remains resilient as vehicle technology accelerates. The narrative of A to Z Auto Repair is thus not merely a tale of tools and procedures; it is a story of disciplined inquiry, collaborative problem-solving, and a relentless focus on safety and reliability.

For readers seeking a concise primer on digital workflows in automotive service, an introductory exploration is available in the hello-world resource. This foundational piece helps illuminate how digital inspections, online estimates, and data-driven diagnostics converge to improve transparency and outcomes. The broader literature continues to emphasize that the most effective diagnostic practices are those that balance rigorous testing with practical sensitivity to customer needs, cost considerations, and real-world driving conditions. As vehicles become still more complex, the diagnostic mind-set—curiosity tempered by method, hypothesis tested by data—will remain the true engine of repair quality. If you want to explore foundational diagnostics concepts at a broader level, see the linked primer linked in this chapter’s text: hello-world.

In summary, the technological foundations of auto repair are not merely about gadgets; they shape the very way work is planned, executed, and verified. Diagnostic workflows translate signal into service, data into decisions, and complexity into safety. The result is a cohesive, auditable process that supports reliable outcomes for customers, sustainable profitability for shops, and a clear path forward as vehicles continue to evolve—the core promise of A to Z Auto Repair in an era defined by electronic ecosystems and intelligent systems. External resources that expand on the diagnostic standards and data pathways mentioned here can be consulted for deeper understanding: https://en.wikipedia.org/wiki/On-board_diagnostics.

Flowing for First-Time Fixes: Designing a Lean, Tool-Rich Shop for A to Z Auto Repair

Every successful auto repair operation begins with the space that houses it. The tools, layout, and people who move through the shop all cohere when the floor plan mirrors the actual work—minimizing walking, reducing waits, and sharpening the alignment between diagnostic insight and hands-on execution. The goal is a shop that breathes efficiency without sacrificing safety or quality. When a car arrives, it should move through a clear sequence: intake and inspection, precise diagnostics, targeted repair, QA, and handoff to the customer. That sequence is made possible not by luck but by deliberate design. In practice, the heart of a well-oiled shop sits in a thoughtfully arranged array of zones, each with clear responsibilities and fluid handoffs. Inbound and parts handling set the tempo, the diagnostic and EMS zone acts as the brain, the repair bays form the muscle, and the tire, alignment, and heavy-equipment areas provide specialized leverage. A clean, 5S-minded environment—sort, set in order, shine, standardize, sustain—ensures tools are where technicians expect them to be and the floor remains a safe, predictable place to work. Shadow boards, correctly labeled bins, and near-at-hand test equipment that mirrors the technician’s mental model thread through this logic. The point is not to clutter the shop with gadgets but to build a reliable, visible workflow where every tool and every part has a home and every action has a purpose. Our Hello World post reminds us that starting simple and scaling with discipline yields durable momentum; in this setting, that means establishing a baseline layout that can grow as service mix evolves. Hello World is a gentle nod here to the idea that foundational practices, repeated well, become the backbone of a high-performance shop.

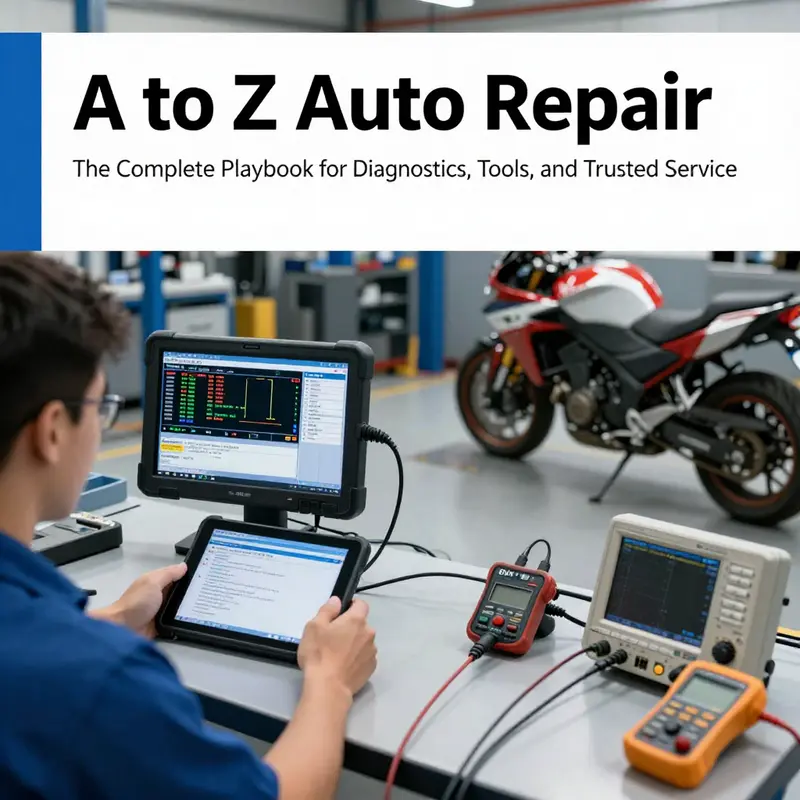

The diagnostic and EMS zone is more than a cluster of machines; it is a cockpit for data and decisions. Modern vehicles present streams of fault codes, live sensor data, and a cascade of module interactions. A diagnostic workstation should be equipped with OE-level software, a dependable harnessing strategy, and a power-agnostic testbed that can emulate real-world conditions without subjecting the technician to unnecessary risk. The hands-on testing—bidirectional controls, electrical measurements, even targeted component activation—transforms abstract codes into tangible truths. This demands not only the right tools but a layout that minimizes the arc between data gathering and physical reaction. When a fault is suspected, the technician should be able to pivot from a screen to a bench and back again without detours or bottlenecks. The equipment mix must include high-quality oscilloscopes, DVOMs, lab power supplies, and breakout boxes that are durable and easy to recalibrate. In the same breath, the shop must protect data integrity and privacy, ensuring software licenses and diagnostic access stay tightly managed. The flow from diagnostic insight to repair must be a straight line, not a series of detours through cluttered aisles or crowded bays.

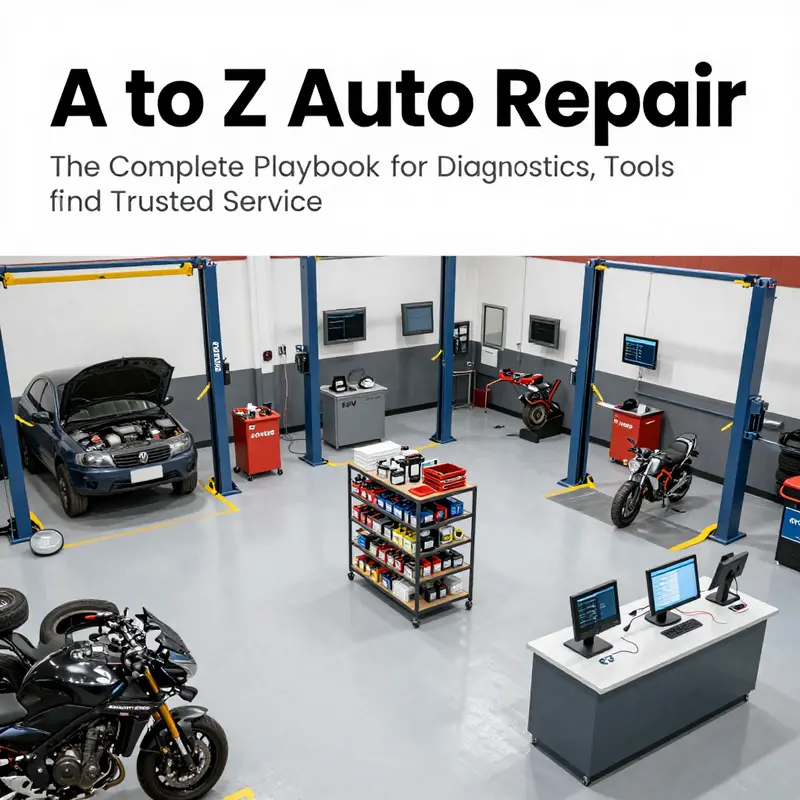

Beyond diagnostics, the repair and service bays require a deliberate balance of specialization and flexibility. A linear, or even a U-shaped, bay arrangement helps technicians move from discovery to remediation with minimal backtracking. Having dedicated zones for engine, transmission, electrical, and electronics work accelerates throughputs, but the real win comes from repositioning high-demand tasks closer to the diagnostic heart. When brakes, steering, or suspension work is needed, those bays should be in comfortable reach of a central parts room and a shadow-boarded tool crib, minimizing the need to leave the bay for common consumables. A tire and wheel area deserves its own focus, equipped with a floor drain and waste management, because tires bring a different cadence to the day and demand a flow that isolates wheel work from precision engine repairs. If space allows, a small, dedicated area for heavy equipment, welding, or advanced fabrication ensures carts, jigs, and lifting devices do not interrupt routine repair work. The shop’s physical design must also account for safety, with clear separation between high-velocity vehicle movement, exhaust and ventilation zones, and chemical storage. The ventilation plan should extend beyond the obvious odor control; it must actively manage fumes from solvents, refrigerants, and high-voltage service where applicable.

A central, centralized parts room anchors the whole operation. Clear labeling, BIN systems, and smart, just-in-time stocking reduce the frantic scramble that steals minutes and invites error. Shadow boards near each technician’s primary workspace reinforce a personal habit of organization, while color-coded storage channels help teams identify, at a glance, where a given category of fasteners, seals, or sensors should live. The office corner and customer-facing area should provide visibility into the bays, either through windows or camera feeds, so service writers and customers share a common narrative about what is happening with the vehicle. The shop floor should evolve with demand. It is both prudent and practical to plan for phased growth: start with essential bays, diagnostic stations, and a compact wheel/tire zone, then add a second lift, another diagnostic tool, or a larger parts vault as the service mix shifts toward more complex electronics, ADAS calibrations, or EV maintenance.

The floor plan itself is a language. Linear layouts offer clear progressions—intake to diagnostics to repair to QA—with straightforward wiring and utility routes. A cellular layout, where each cell supports a discrete service family, can yield speed when demand concentrates in specific areas. A horseshoe or radial setup around the diagnostic hub compresses travel and creates a natural rhythm as technicians flow from test to torque, from data sheet to torque wrench. Whatever the geometry, the aisle widths matter. Main thoroughfares must breathe—six to eight feet as a baseline, with wider passes near lifts and across main work lanes to accommodate equipment movement and for safety clearance. Height-adjustable benches offer ergonomic relief for long days bent over a busier, more ambitious repair schedule. Adequate lighting is non-negotiable; bright, uniform illumination over every bay reduces errors and fatigue. Floor coatings should resist chemical spills, provide traction, and be easy to clean—because a tidy floor is a reliable indicator of a disciplined shop.

The list of tools and equipment that a shop should curate reads like a map of the vehicle’s life story. Lifts come first: two-post for general work, four-post for storage and alignment capabilities, and perhaps scissor lifts for tight spaces. Jacks and stands must be robust, with reliable locking mechanisms and clear load ratings. Diagnostic ecosystems demand a spectrum of tools—from OEM-capable scan tools to flexible pass-through interfaces and cloud-connected platforms that stay current with ongoing software updates. Electrical work benefits from a spectrum of meters, scopes, and stable test benches that can cradle the complexity of modern circuits. For wheel and tire work, you need a capable changer and balancer, plus measurement tools and a calibrated alignment system, all within a zone that supports orderly waste management. Engine and transmission work requires engine hoists, trans jacks, specialty tools, and a clean, organized work area that tolerates the occasional spill of lubricants and solvents. Refrigerant handling, battery diagnostics, and a robust fluids management system round out the essentials. Safety gear looms large here: PPE, proper hazmat handling, spill kits, and an eyewear-first culture that keeps everyone vigilant.

Economic realities shape the practicalities of implementing this design. A balanced mix of used and new tools, phased purchases, and a clear maintenance schedule keeps depreciation predictable while enabling steady growth. The recommended equipment footprint and ballpark costs should be treated as a living plan, adaptable to the shop’s scale and service mix. An executive approach to capital budgeting is essential: prioritize essential diagnostic capability, robust lifts, and core hand tools before expanding into high-end welding or specialized calibration rigs. Importantly, a shop’s management system underpins every physical asset. A capable shop management platform ties work orders, parts, time-tracking, and customer communication to the physical flow. It ensures the right parts are on hand when needed and that technicians move with purpose rather than guesswork.

Implementation follows a practical rhythm. Start by assessing current footprint and future ambitions, then map zones and lanes. Draft a schematic of bays, lifts, diagnostic stations, and the parts room, making utility access a first-class consideration. Phase in essential equipment, then phase in more advanced capabilities as service demand grows. Adopt 5S routines as a daily habit, and train teams to trust the plan as the plan grows. Track metrics that matter: throughput time, technician utilization, first-time fix rate, and space utilization. The result is more than a shop; it is a disciplined system that translates diagnostic insight into reliable, repeatable repair outcomes.

Customization remains crucial. A single-shop layout must reflect service mix and local demand. If you emphasize electrical work or ADAS calibration, you’ll want more robust electrical benches and an alignment-ready bay. If tires and brakes dominate, the tire service area becomes the hub of activity. The plan should also respect local safety codes and environmental requirements, which can influence ventilation, spill containment, and waste handling. The goal is not to create rigidity but to foster a scalable, repeatable process that can flex with the industry’s evolution.

External resources and ongoing learning play a role too. For safety and compliance guidance, turn to established standards and best practices as you grow. And as you refine the shop, remember that the right floor plan, the right toolkit, and the right management practices can turn visits into trust and repairs into reliable outcomes. For practical inspiration and shared experiences, explore related discussions in our broader content ecosystem, and consider visiting external references to deepen your understanding of workplace safety and efficiency. Finally, to keep the flow honest and clear, refer to external safety guidelines at the following resource: https://www.osha.gov

null

null

Regulatory Currents and Global Tides: Navigating Environmental, Geopolitical, and Safety Demands in A to Z Auto Repair

The auto repair landscape is more than a service economy of wrenches and diagnostics; it sits at the intersection of law, stewardship, and volatile global dynamics. Shops operate within a framework that expects safety for workers, responsibility for the environment, and transparency for customers, all while contending with shifts in trade, data access, and technology. In this milieu, the chapter on regulatory, geopolitical, and environmental context becomes a map to understand why every documented procedure, every waste stream, and every supplier decision matters to a shop’s long-term viability. The end-to-end journey of a vehicle in a repair cycle—from intake to repair to test drive—unfolds within an ecosystem that rewards disciplined compliance, meticulous recordkeeping, and proactive risk management. The goal is not merely to avoid penalties but to build trust, resilience, and efficiency in a world where rules evolve as vehicles become more connected and complex. In this sense, the regulatory environment is not a constraint so much as a framework that, if navigated well, reinforces safety, quality, and customer confidence.

At the federal level, several pillars shape daily shop life. Hazardous waste management under the Resource Conservation and Recovery Act (RCRA) guides how shops classify, store, and dispose of used oil, solvents, and degreasers. The categorization of generators—very small, small, or large—drives manifest documentation, inspection cadence, and contingency planning. The SPCC rule adds another layer for facilities storing oil above threshold amounts, prompting spill prevention plans and secondary containment strategies. Refrigerant handling sits under the Clean Air Act, with EPA Section 608 certification ensuring technicians can recover, reclaim, and responsibly vent or dispose of refrigerants. This is not only about compliance; it is a critical environmental firewall that protects the atmosphere and ultimately affects vehicle emissions. Hazard communication, encapsulated in OSHA’s HazCom standard, requires labeling, safety data sheets, and training so every technician understands how to work safely with chemicals, batteries, and flammable liquids. The broader safety net includes lockout/tagout procedures to control hazardous energy during electrical servicing and adherence to fire and ventilation codes to minimize risks in crowded shop floors. The regulatory baseline then extends to consumer protections, recall management, and, increasingly, data access and repair rights, which bridge regulatory policy with the evolving information architecture of modern vehicles.

Environmental considerations in auto repair hinge on managing six key streams with discipline: used oil and other hazardous fluids, refrigerants, batteries, solvents and coatings, air emissions from VOC-containing products, and water or surface discharges from wash operations. Effective practice demands a well-structured waste hierarchy: minimize generation, segregate streams at the source, and contract with licensed, reputable recyclers or treatment facilities that provide chain-of-custody documentation. Used oil should never blend with antifreeze or solvents; all containers must be properly labeled, stored in compliant cabinets, and protected from leaks. Refrigerants require not only certified handling but also ongoing equipment maintenance to prevent leaks and capture gases efficiently. Batteries, whether lead-acid or lithium-based, demand universal waste management where applicable, with attention to isolation to prevent short circuits and to downstream recycling streams. VOC control in paints and degreasers means prioritizing low-VOC products when feasible, ensuring adequate ventilation, and using fume capture or local exhaust systems. Spill response readiness—kits, absorbents, eyewash stations, and trained staff—reflects a culture that treats safety as a shared responsibility rather than an afterthought. All of this creates a tangible impact on daily operations: storage space, labeling schemes, training timetables, and waste manifests become routine elements of the business, not episodic tasks.

Geopolitical currents increasingly shape the availability, cost, and assortment of parts, tools, and software necessary for modern repairs. Global supply chains are sensitive to policy shifts, tariffs, sanctions, and regional trade agreements. A comprehensive approach recognizes that a sudden parts shortage or price spike can ripple through inventory planning, technician schedule optimization, and customer communications. Regional integration agreements—such as cross-border content and compliance rules—may impose requirements that alter sourcing strategies and documentation standards. Beyond physical parts, the accessibility of diagnostic data and service information is a political topic with real consequences for shop capability, particularly for newer vehicles with advanced electronics and high-voltage systems. The so-called Right to Repair movements underscore the tension between proprietary tool ecosystems and independent shops’ ability to diagnose and service vehicles. For A to Z Auto Repair, anticipating these debates means building flexible procurement networks, investing in multi-vendor diagnostic capabilities, and staying vigilant about licensing and data-access policies. Sanctions and export controls can constrain access to novel batteries, charging hardware, or sophisticated calibration software in rare cases, reminding shops that geopolitical risk is not abstract—it can alter the tools available for everyday work.

Operationally, translating this complex framework into a practical, defensible program requires a coherent compliance architecture. A written environmental policy and a formal compliance plan clarify roles, responsibilities, and recordkeeping expectations. Centralized access to safety data sheets, regulatory references, and waste manifests reduces the likelihood of misfiling and facilitates audits. Standard operating procedures should articulate hazardous material handling, spill response, and emergency actions, while ongoing training ensures staff stay current with HazCom, refrigerant handling, and fire safety. Inventory management must explicitly account for waste streams and ensure that disposal documentation travels with every batch of waste to licensed contractors. Facility design should reflect the importance of ventilation, containment, and safe storage, with separate zones for flammable liquids, batteries, and refrigerants. A resilient shop also diversifies its supply base to guard against single-source vulnerabilities and tracks geopolitical developments that could influence embedded software licenses or data access policies. Transparent customer communications—about recycling practices, environmental commitments, and safety measures—support trust and loyalty, turning compliance from a cost center into a value proposition.

For the reader seeking practical entry points, one simple step is to connect regulatory diligence with customer-facing transparency. The way information is framed online, from digital vehicle health reports to post-repair explanations, can reinforce or undermine trust. A practical primer to this approach is illustrated in a simple blog post that introduces the idea of transparent communication and digital inspections—an opportunity to anchor your shop’s environmental and safety commitments in everyday practice. See the Hello World post for a starting point on how we present information online in approachable terms. Hello World

As a closing recap, the regulatory, environmental, and geopolitical context is not a static backdrop but a vital operating terrain. It shapes risk management, informs investment in training and tooling, and guides how a shop communicates with customers and regulators alike. The future will demand even more robust data access policies, cleaner operations, and a deeper integration of sustainability into service models. A to Z Auto Repair’s path forward should weave compliance into culture, build agility into procurement, and elevate the customer experience with open dialogue about safety, responsibility, and the life cycle of every vehicle that crosses the bay doors. External guidance, such as federal and state environmental resources, remains essential touchpoints for staying compliant and responsible in the years ahead. External resource: https://www.epa.gov/hw

From Local Garages to Connected Communities: Societal Ripples, Customer Experience, and the Road Ahead for A to Z Auto Repair

The auto repair world operates at the intersection of craft and consequence, where every diagnostic scan, every parts order, and every customer conversation reverberates through local economies, daily mobility, and shared expectations about safety and reliability. In the A to Z auto repair ecosystem, the societal footprint is not a footnote but a living, evolving force. It begins with the shop on the corner, a workforce that learns by doing and by training, and a customer base that depends on timely service to keep families, commuters, and small businesses moving. The health of these micro-economies matters because repair shops are often anchors of skills transfer and employment in their communities. They host apprenticeships, sponsor local training partnerships, and create pathways for people to enter skilled trades where demand remains resilient even as technology transforms the work itself. When a neighborhood shop thrives, nearby restaurants stay open later, suppliers carry a steadier stream of orders, and families experience less anxiety about vehicle reliability during critical periods of the year. In this sense, the A to Z ecosystem contributes to social cohesion as much as it delivers a service like any other.

Mobility access is another crucial dimension. Modern vehicles encode a map of needs—maintenance intervals, recall campaigns, software updates, and safety calibrations—that only a capable shop can translate into action. When communities face shortages of skilled technicians or parts, turnout for routine maintenance declines, and the risk of unexpected failures rises. In turn, that erosion affects school runs, shifts at factories, and emergency responses. A well run shop supports smoother commutes and better predictability for households balancing tight budgets and time constraints. This is why transparency in scheduling, pricing, and repair status matters beyond customer satisfaction; it underpins social trust in the local economy. As vehicles grow more connected, the shop’s role expands from fixer of broken machinery to steward of data-informed decision-making. Digital inspections, photos, and condition reports become bridges that connect shop expertise to consumer confidence, enabling customers to understand the rationale behind each recommendation rather than simply accepting a bill. The shift toward digital transparency creates a shared language for safety and reliability, strengthening the social contract between repair providers and the communities they serve. A link in this chain is the way shops communicate with customers about what was found, what it costs, and what remains under warranty or service coverage. The practice of recording and presenting service history also supports continuity of care when a vehicle changes hands between a family, an employer, or a fleet operator.

Environmental stewardship sits alongside mobility and trust as a pillar of societal impact. Shops increasingly adopt green practices for fluid management, battery recycling, and the proper disposal of hazardous waste. The transition to electrified propulsion brings new environmental considerations, including how high-voltage components are handled, how refrigerants are recovered, and how battery health programs inform end-of-life decisions. In communities where environmental concerns are paramount, shops that publish transparent sustainability metrics—shop waste diversion rates, energy efficiency in the facility, and the lifecycle analysis of common consumables—build credibility with customers who are weighing not just price but the broader societal footprint of their purchases. These practices extend to the procurement side as well: choosing parts and vendors with responsible manufacturing and packaging reduces waste and supports local procurement ecosystems that reinforce regional resilience. The economic and environmental calculus together shapes a more equitable model of maintenance, because affordability must be balanced with stewardship and long-term reliability. Price transparency, fair labor practices, and accessible financing options are not merely conveniences; they are enablers of who can access essential maintenance and how often they can do so without compromising essential budgets.

The customer experience, in turn, is the crucible in which society and technology meet daily needs. The pathway from intake to repair is increasingly mediated by digital tools that empower customers to participate in the process. Online estimates, electronic work orders, and digital inspections with photo documentation turn a date-and-time interaction into a richer conversation about what the vehicle needs and why. The goal is not to overwhelm but to illuminate choices so customers can decide with clarity and confidence. The best shops cultivate trust through consistency: accurate diagnostics, transparent pricing, and warranties that stand behind the work. The quality of the customer journey is measured not only by the speed of delivery but by the meaningfulness of the information customers receive. A well-informed client can verify whether a recommended service aligns with vehicle age, mileage, and usage pattern, and can understand how future maintenance could prevent costlier repairs. This emphasis on clarity reduces friction and strengthens loyalty, especially when customers encounter a series of visits that demonstrate a reliable pattern of improvements in performance and longevity. Digital enablement—appointment reminders, status alerts, and remote inquiries—contributes to a smoother experience while also collecting data that helps shops refine their workflow, triage dilemmas, and forecast demand with greater accuracy. The customer journey, therefore, becomes a living score of the shop’s competence, empathy, and reliability.

Within this evolving experience, the role of information is pivotal. Diagnostic data, once housed only within shop systems, increasingly travels with the vehicle through telematics and connected-car services. This permeates the service model in two ways: it broadens the diagnostic lens to include real-time vehicle behavior and it introduces heightened responsibility around data privacy and cybersecurity. As vehicles share more data, shops must balance the advantages of proactive care with the need to protect personal information and safeguard access to vehicle interfaces against unauthorized manipulation. In parallel, the rise of ADAS calibration, high-voltage safety protocols, and software reflash capabilities reframes what it means to be a competent shop. The technician’s toolkit expands beyond mechanical skill to include software literacy, calibration procedures, and a disciplined approach to software licensing and customer consent. The learning curve is steep, but the payoff is clear: fewer misdiagnoses, more precise repairs, and longer intervals between visits for customers who experience genuine improvements in vehicle performance. The internal dialogue within the shop also shifts toward a culture of continuous improvement, standardization, and cross-functional collaboration—an environment where technicians, service advisors, and digital specialists work as a cohesive team. This cultural alignment underpins both the short-term success of a repair and the long-term resilience of the business in a market that prizes speed, accuracy, and transparency.

Looking forward, the industry faces a convergence of trends that will redefine the repair experience. The shift from internal-combustion engines to electrified propulsion and to increasingly autonomous systems implies a growing demand for high-voltage safety training, battery health diagnostics, and software update services. Telematics, predictive maintenance, and remote diagnostics will enable shops to anticipate failures before customers notice symptoms, turning maintenance from a reactive event into a proactive service. These capabilities, however, carry regulatory and ethical implications. Data privacy and cybersecurity policies will shape who can access what data, under what conditions, and with what protections. Compliance with environmental rules will grow more nuanced as battery recycling programs mature and as new fluids and refrigerants enter the shop’s repertoire. The competitive landscape will also evolve, with independents, dealership service centers, and hybrid models each leveraging different strengths—local trust and speed for independents, access to advanced software and OEM updates for dealerships, and a blend of convenience and price transparency across multi-location networks. Across all models, the customer experience will hinge on the integrity of the diagnostic process, the fairness of pricing, and the reliability of the communication that travels from the first phone call to the final test drive.

In this dynamic context, strategy for a hypothetical A to Z Auto Repair demands investments that align people, processes, and technology with the evolving expectations of customers and regulators. It calls for ongoing technician training, a thoughtful parts network, and a facility design that accommodates both traditional repairs and high-voltage work in a safe, efficient layout. It requires partnering with vendors who can provide consistent calibration data, licensable software, and reliable parts with transparent warranties. And it asks for a deliberate emphasis on the customer journey—listening to concerns, offering clear options, and following through with measurable outcomes. All of these elements weave together to form a service model that not only fixes cars but also sustains communities, builds trust, and prepares the business for a future where vehicles are more connected, more complex, and more dependent on the human relationships that make maintenance a shared responsibility. The path ahead is not merely about keeping engines running; it is about preserving mobility as a public good, ensuring that every repair decision reinforces safety, accessibility, and opportunity for the people who rely on their vehicles every day. For readers seeking broader context on how repair policies intersect with safety standards and consumer protection, see the external resource referenced at the end of this chapter. Meanwhile, the navigation toward a more transparent, data-informed, and skill-rich repair ecosystem continues, one appointment, one diagnostic, and one trusted customer interaction at a time. Hello World blog post offers a light-hearted reminder that even in highly technical work, clear communication and continuous learning remain essential touchstones. https://motorworksautorepair.com/blog/hello-world/. For further regulatory context on recalls and safety, refer to public safety resources at https://www.nhtsa.gov.

Final thoughts

A to Z Auto Repair stands as a comprehensive framework for modern vehicle care that serves riders, owners, distributors, and repair businesses alike. By anchoring the work in solid diagnostic foundations, investing in purpose-built tools and shop layouts, navigating the economics of labor and pricing with clarity, complying with safety and environmental standards, and embracing the expectations of today’s connected customers, the ecosystem becomes more predictable, safer, and more capable of adapting to tomorrow’s vehicles. The five facets—technology, tooling, economics, regulation, and society—do not operate in silos; they reinforce one another to deliver faster, more accurate repairs, better customer conversations, and resilient operations across the entire A to Z Auto Repair spectrum. The road ahead will demand continued investment in technician training, data security, and agile processes, but it also offers opportunities to create lasting value for motorcycle and auto owners, to optimize parts sourcing, and to elevate the role of repair shops as trusted partners in keeping vehicles safe and reliable.